Any heat source that burns fuel emits a byproduct - toxic exhaust gases. Accordingly, installing a heat generator in a private house or apartment involves installing a chimney pipe that discharges harmful gases to the street. In terms of labor costs and price, these works make up a significant portion of the entire installation. We decided to highlight this stage and specifically explain how to properly make an inexpensive chimney for a gas boiler. Let's not ignore other types of heating units.

Gas duct options for a country house

To remove combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

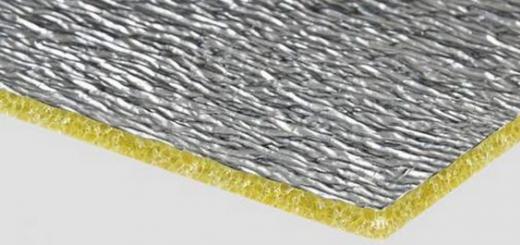

- three-layer modular sandwich made of stainless steel with non-flammable insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- a brick block with a stainless pipe insert, covered on the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Note. Gas boilers with a closed combustion chamber (otherwise called forced-air or turbocharged) should be equipped with coaxial chimneys. In fact, this is a double-walled metal pipe that can simultaneously suck in combustion air from the street and throw smoke out.

Let us explain why it is impossible to build a traditional brick chimney or install an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of combustion of hydrocarbons. From contact with cold walls, moisture falls out as condensation, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and others (using diesel fuel and liquefied propane) operate periodically, frost has time to capture moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and outside, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

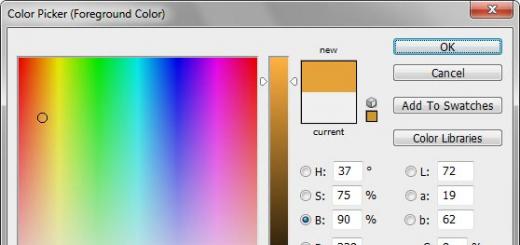

Ordinary iron pipe insulated with non-flammable kaolin wool

Ordinary iron pipe insulated with non-flammable kaolin wool For reference. On the outside, unsightly, dirty streaks form at the joints of single-walled metal chimneys.

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for DIY installation, we recommend using a stainless steel sandwich pipe. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, making work difficult. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of the sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the funds. Systems like Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless steel and polymer inserts are used for reconstruction - lining of existing brick channels, previously built according to old designs. It is unprofitable and pointless to deliberately fence such a structure.

Flue option with ceramic insert

Flue option with ceramic insert Advice. It is better to purchase sandwich chimneys made entirely of stainless steel - they will last longer and maintain a presentable appearance. If the project budget is very limited, take a modular system lined with galvanized metal - the structure will last at least 20 years.

A turbocharged gas boiler can also be connected to a conventional vertical chimney, organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct leading to the roof has already been installed in a private house. In other cases, a coaxial pipe is installed (shown in the photo) - this is the most economical and correct option.

The last, cheapest way to build a chimney deserves attention: make a sandwich for a gas boiler with your own hands. A stainless steel pipe is taken, wrapped in basalt wool of the required thickness and covered with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of a solid fuel boiler

The operating mode of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 °C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot settling on the inner walls. Periodically it ignites, causing the pipe to heat up to 400-600 degrees.

The following types of chimneys are suitable for solid fuel boilers:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

A brick flue of rectangular cross-section 270 x 140 mm is lined with an oval stainless pipe

A brick flue of rectangular cross-section 270 x 140 mm is lined with an oval stainless pipe Asbestos pipes are contraindicated for installation on TT boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to line it with a stainless insert. The FuranFlex polymer sleeve will not work - the maximum operating temperature is only 250 °C.

Design and procurement of materials

To select the correct parts for a modular chimney and calculate the amount of materials, perform a number of preparatory steps:

- Study the requirements for gas boiler chimneys.

- Determine the installation method, channel diameter and thermal insulation thickness.

- Draw a diagram and make a list of materials.

For reference. As a rule, the installation of a heat source in a country house begins with the installation of flue ducts and ventilation exhaust pipes. Placement of the heat generator in the boiler room and connection to the heating is done secondarily.

It is better to build internal channels during the construction of a house

It is better to build internal channels during the construction of a house The buzz words “calculation” and “project” in the list above may confuse some homeowners. In reality, these steps do not pose a big problem. So that you don’t have to look for regulations on the installation of chimneys, we will provide them here.

Regulatory requirements for chimney pipes

The instructions given in the building codes and regulations (SNiP) must be taken into account for a simple reason: the fuel supplier company will not accept the gas boiler into operation and will not connect it to the main line if the gas duct is installed incorrectly. The requirements sound like this:

In the lower blind part of the vertical section there is a hatch for cleaning (inspection) and a condensate collector with a discharge fitting. The section of pipe near the boiler can be made single-walled, but the sandwich must go outside or into the adjacent attic.

Important. The minimum height of the smoke exhaust structure should be 6 m, counting from the gas burner or grate of the solid fuel boiler.

Determine the diameter and method of laying

The solution to the first question is found in the requirements for chimney ducts: look at the connecting dimensions in the heat generator’s data sheet and select a sandwich chimney with an identical or larger diameter than the outlet pipe.

Indentations when installing a coaxial chimney

Indentations when installing a coaxial chimney Question two: how to choose the thickness of the thermal insulation of the sandwich, because the manufacturer offers at least 2 options - 5 and 10 cm. To protect the chimney connected to the gas boiler from excessive condensation and freezing, an insulation thickness of 50 mm is sufficient. 10 cm insulation should be used in northern regions with critically low winter temperatures.

It remains to choose a laying method from two possible ones:

- bringing the horizontal section out through the wall and connecting it to a vertical attached chimney;

- pass a vertical pipe through the ceilings, attic and roof, that is, lay a smoke exhaust duct inside the house.

Installation options for conventional and coaxial smoke ducts

Installation options for conventional and coaxial smoke ducts Note. Both options are suitable for installing coaxial flue ducts, but in most cases the first one is implemented with a passage through the outer wall.

Laying the pipe along the shortest path to the street and lifting the pipe along the wall is the simplest and cheapest way. You will have to cross only one structure, and in the second option - at least two. Plus sealing of the junction of the roofing covering and the chimney.

On the second floor, such a structure will have to be sewn up

On the second floor, such a structure will have to be sewn up Try in every possible way to avoid indoor installation, since in a house with two floors or an attic roof, a healthy pipe will inevitably pass through the rooms, taking up useful space. Draw a sectional diagram of the building and a passing chimney if it cannot be mounted outside.

We make a list of parts according to the diagram

To install an attached chimney connected to a gas or solid fuel boiler, you will need the following elements of a modular sandwich:

- tee with 89° branch pipe for joining the horizontal section with the vertical one;

- tee with inspection hatch;

- section with condensate collector;

- a section of a single-wall pipe and a coupling for connecting a heat generator;

- transition ordinary pipe - sandwich;

- straight sections - the number and length are selected according to the length of the gas duct;

- 2 30° elbows are required to bypass the roof overhang;

- an upper cap in the form of a nozzle that protects the insulation of the last section from precipitation.

Detailed diagram for outdoor installation

Detailed diagram for outdoor installation Important point. The installation of fungi and decorative canopies on the chimney of a gas boiler is prohibited. During periods of extreme frost, the top will freeze and the flow area will decrease, which is dangerous for the lives of residents.

The fastening parts will require wall clamps with brackets and a support platform that can support the weight of the mounted structure. If you plan to install a flue inside the building, you will additionally need ready-made units for passage through the ceilings, a roofing sealing lining (otherwise known as kryza, master - flush) and 90° elbows for installing a chimney in the boiler room.

Installing a sandwich chimney

The first stage of installing an attached structure is punching a hole in the outer wall and preparing for laying a horizontal section. In a house built from combustible materials, the opening is made taking into account the fire safety clearance (38 cm from the edge of the wooden wall to the inner pipe of the sandwich) and the installation of the flange of the passage unit, as shown in the photo.

Note. In fireproof structures made of bricks and foam blocks, a fireproof cutting device is not required. A metal sleeve is placed into the opening and a section of the flue is inserted, sealing the gap with non-flammable material.

Work on installing the modular sandwich and connecting to the gas boiler is carried out in the following sequence:

Reminder. In a wooden house, seal the gap between the ends of the wall and the intersecting pipe with basalt fiber, and then install metal flanges on both sides.

Straight sections are simply inserted into each other and secured with clamps; there is no need to coat the joints with sealants. If trimming is necessary, then the lower end of the section is shortened, where the insulation is located flush with the metal linings. A protective cone is placed on the upper edge of the chimney.

Detailing for internal installation

Detailing for internal installation Laying a smoke exhaust duct inside a building is done in the same way, only you will have to go through the structure twice, or even three times. The same rules for constructing cuttings when crossing flammable floors and walls are observed everywhere. At the end, you need to carefully seal the roof where the pipe passes, as is done in the video:

Conclusion

A chimney is far from a simple structure, hence the large number of regulatory requirements. In this regard, it is easier to install a coaxial pipe connected to a gas boiler with a closed combustion chamber - it is not designed to create natural draft. One difference: a horizontal double-walled flue is installed with a slope away from the heat generator so that the condensate flows out.

Initially, the correct installation of the smoke duct will be checked by specialists who will come to connect the boiler to the gas main. If you make serious mistakes during the installation process, you will be forced to redo the pipe. Minor flaws will appear during operation, and you will also have to eliminate them yourself.

To remove combustion products generated during the combustion of natural gas, chimneys of various designs are used. Previously, chimneys were built only from asbestos-cement pipes and bricks. Nowadays, a smoke exhaust pipe can be assembled from durable and lightweight materials that are much less expensive.

Requirements for chimneys for gas boilers

Design, assembly, installation and other activities aimed at installing a smoke duct are regulated by regulatory documents that clearly and clearly state the basic requirements for these structures.

For floor-mounted and wall-mounted gas boilers, a steel chimney is most often installedRegulatory documents regulating the installation of chimneys for gas boilers include SNiP 2.04.05–91 “Heating, ventilation and air conditioning”, as well as DBN V.2.5–20–2001 “Internal gas supply arrangement”.

Based on these documents, the following requirements are imposed on smoke exhaust structures that will be used in conjunction with heating boilers:

The above requirements are general and must be met in all cases without exception. When installing a chimney, you should remember that even small deviations from the values required by regulatory documents can cause a decrease in the service life of the chimney, and in some cases lead to more serious consequences.

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through nozzles, and a heat exchanger, which is heated by the energy obtained during gas combustion. The gas burner is located in the combustion chamber. Heat movement occurs using a circular pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules, allowing the equipment to be used in autonomous mode. When choosing a chimney, pay attention to the type of boiler combustion chamber. The method of intake of air necessary for gas combustion, and as a result, the optimal type of chimney, will depend on its design.

Different types of chimneys are suitable for different types of combustion chambers

Different types of chimneys are suitable for different types of combustion chambers The combustion chamber of gas boilers is of two types:

- open - provides natural traction. The air is taken from the room in which the heating equipment is installed. The removal of combustion products is carried out through natural draft using a chimney with an exit through the roof;

- closed - provides forced traction. Air intake for fuel combustion comes from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. To simultaneously remove flue gases and intake fresh air, a coaxial type chimney is used, which is vented outside through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or manufacture a chimney suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross-section is fixed inside a pipe of a larger diameter using special racks. Carbon dioxide and other combustion products are removed through the internal channel, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

- internal - chimneys made of metal, brick or ceramics. They are available in both single-wall and insulated double-wall constructions. Positioned vertically upward. There may be several elbows with a 30° offset;

- external - coaxial or sandwich chimneys. They are also located vertically upward, but the chimney is led out horizontally through the load-bearing wall. After the pipe has been removed, a 90° swivel elbow and support brackets are installed to allow installation in the desired direction.

The chimney can be vented outside through a wall in the immediate vicinity of the boiler or in the traditional way through the roof

The chimney can be vented outside through a wall in the immediate vicinity of the boiler or in the traditional way through the roof When choosing a chimney installation method, you should take into account the size of the building in which the equipment is located. For small buildings, it is more advisable to use external chimneys, as they allow the chimney to be taken outside the premises.

In other cases, you should build on your personal capabilities. If space allows and it is possible to provide high-quality insulation where the pipe passes through the ceilings, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.

Do-it-yourself chimneys for gas boilers

As with other heating equipment, a chimney for a gas boiler can be purchased in specialized stores. This will be a standard modular product, which is selected taking into account the type of boiler and its power.

What to make a chimney for a gas boiler from

A chimney for a gas boiler can be made from various materials. The main thing is that the material is non-flammable, resistant to chemically aggressive environments and does not allow gases to pass through the smoke duct.

For the manufacture of steel chimney parts, steel with the addition of molybdenum, titanium and nickel is used

For the manufacture of steel chimney parts, steel with the addition of molybdenum, titanium and nickel is used Taking into account regulatory requirements, the following materials are used for the manufacture of the chimney:

- brick is a traditional material for the manufacture of chimneys for solid fuel stoves. For laying the chimney, class A or B stove fire-resistant bricks are used. When using gas equipment, a combined approach is often used, when a steel or asbestos-cement pipe is used as an internal channel;

- steel - used to create chimneys of any configuration. The quality and heat resistance of a material is determined by its alloy, which is indicated by a special marking. Thus, for the manufacture of chimneys, products made of AISI 316i, AISI 321 or AISI 310S steel are better suited;

- ceramics - a fired mixture of clay and sand, from which combined chimneys are made. The internal channel is made of a ceramic pipe of a certain cross-section. A box made of expanded clay concrete shell or brick is used as a protective casing.

If we carry out a detailed comparison, the best material in terms of price and quality ratio is galvanized steel AISI 321 and AISI 310S. Chimneys made of such steel are designed for flue gas temperatures up to 800 and 1000 o C, respectively.

Ceramic chimneys have high performance characteristics, but their cost is noticeably higher than their steel counterparts

Ceramic chimneys have high performance characteristics, but their cost is noticeably higher than their steel counterparts The average service life of steel chimneys is 13–17 years, but due to the high standardization of parts, there is no need to completely change the design. During repairs, only part of the burnt-out modules are replaced.

Ceramic chimneys have high performance characteristics and a service life of more than 50 years, but their cost is noticeably higher than their steel counterparts. Therefore, this type of chimney is recommended to be used only if there is a sufficient amount of funds and you want to build a structure for a long time. The use of brick chimneys in conjunction with gas equipment is unjustified both in terms of labor costs and the final cost of the structure.

How to calculate chimney parameters for a gas boiler

In order to correctly select or manufacture a chimney, it is necessary to calculate the cross-section of the chimney, as well as its height relative to the level of the ridge. The total height of the chimney is selected in accordance with the regulatory rules specified in SNiP 2.04.05–91.

Table: dependence of the chimney cross-section on the power of the gas boiler

To calculate the pipe cross-section, the following formula is used - F = (K ∙ Q) / (4.19 ∙ √ˉ N), where:

- K is a constant value, the value of which varies from 0.02 to 0.03;

- Q is the maximum performance of gas equipment specified in the specification;

- H is the estimated height of the chimney according to SNiP.

For gas boilers, the minimum height of the chimney must be at least 5 m. The height relative to the ridge is selected from the rules described at the beginning of the article. Let us remind you that the minimum height relative to the ridge must be at least 0.5 m.

After the pipe area has been calculated, it is necessary to compare the obtained value with the data shown in the table. If necessary, the calculated diameter of the smoke channel is rounded to a larger value.

DIY chimney installation

To assemble the chimney, single-circuit steel pipes or special sandwich pipes of the required diameter are used. If the first option is chosen, then after assembling the chimney it is recommended to insulate it. In the second case, there is no need to insulate the chimney.

When using a sandwich chimney, additional insulation of the chimney is not required

When using a sandwich chimney, additional insulation of the chimney is not required As an example, we will give the technology for installing a steel chimney for a gas boiler. To assemble the chimney, you will need straight steel pipes 50 or 100 cm long, 30° chimney outlets, a passage box for walls and ceilings, a deflector, crimp clamps and heat-resistant sealant.

If the diameter of the outlet pipe does not match the diameter of the chimney, then an appropriate adapter is used. It is better to use basalt wool as an insulating material.

Installation of a chimney for a gas boiler is carried out in the following sequence:

- A single-wall or insulated pipe is connected to the outlet pipe of the gas boiler. To do this, the pipe is coated with a heat-resistant sealant, after which an adapter is put on it, which is tightened with a crimp clamp.

- A similar approach is used to connect the adapter to the pipe. First, the mounting end of the adapter is treated with sealant. Next, a straight pipe is placed on it to the required depth. After which the connection is tightened with a clamp.

Before assembling the chimney, it is recommended to check its completeness for the presence of all modules and fasteners

Before assembling the chimney, it is recommended to check its completeness for the presence of all modules and fasteners - To bring the chimney through the ceiling, you will need to cut a square hole in it. The size of the hole is selected so that there is a distance of at least 20 cm from the chimney to the ceiling.

- A steel box is mounted into a hole cut into the ceiling. For fastening, steel screws 30–50 mm long are used. Then a pipe is passed through the box, which is mounted on a module connected to the pipe. The space between the pipe and the box is filled with mineralized insulation. The top of the box is closed with a steel plate.

The outlet of the chimney through the ceiling must be insulated with a steel box

The outlet of the chimney through the ceiling must be insulated with a steel box - If, after introducing the pipe into the inter-attic space, its displacement is required, then a 30° elbow is installed according to the scheme described above. In other cases, a straight section of pipe is installed.

- To remove the chimney through the roof, similar actions are performed. First, a square hole of the required size is cut out. Next, a mounting plate with a hole for the pipe is installed. Then a straight section of the chimney is installed. Finally, a conical additional element made of steel or non-flammable plastic is put on the chimney.

A deflector must be installed at the chimney outlet

A deflector must be installed at the chimney outlet - At the final stage, the remaining section of the chimney is installed. A head and a deflector are installed at the end of the pipe. After assembly, the functionality of the assembled structure is checked. To do this, it is enough for the equipment to operate at 50–60% of maximum power for one hour.

When installing an external chimney, a 90° rotary elbow is used. The elbow is connected directly to the adapter, which is also mounted on the gas boiler pipe.

To remove the chimney, you will need to cut a hole in the load-bearing wall. The size of the hole is selected in the same way as in the case of the ceiling and roof. Next, a steel box is mounted in the wall through which the pipe is passed. Basalt or mineral wool is used to fill the box.

To re-rotate the pipe, another 90° elbow is installed. A special support with a bracket is used as a supporting structure, which is installed under the rotating elbow. The installation step of the hanging brackets is 1–1.5 m. Further steps are similar - you need to assemble a chimney from straight products that are connected using clamps and sealant.

Do-it-yourself coaxial chimney for a gas boiler

Before installing a coaxial chimney, you must check the completeness of the purchased product. If any of the elements is missing, then you should replace the missing set with a complete one, which should include:

- pipe with flange;

- coaxial elbow 90 o;

- connection adapter;

- wall trims;

- O-rings;

- connecting clamps;

- decorative rosette;

- mounting screws.

To assemble a coaxial chimney, you must have a complete set of pipes and connecting elements

To assemble a coaxial chimney, you must have a complete set of pipes and connecting elements The installation process of a coaxial chimney consists of the following steps:

Depending on the manufacturer, the composition of the chimney installation kit may differ slightly, but the main elements in the form of an elbow, pipe, clamps and linings must be included in the kit. Before installing a coaxial chimney, it is strongly recommended to study the instructions.

Video: chimney for a gas boiler made of sandwich pipes

How to reduce the temperature of flue gases in a chimney

When natural gas is burned, carbon dioxide, steam, sulfurous salt-forming oxides, etc. are formed. The optimal temperature of the flue gases at the outlet of the chimney should be 100–110 o C.

If the temperature of the flue gases is below the dew point, that is, the condensation temperature of the air, then the water vapor contained in the combustion products will settle on the walls of the chimney. If this happens constantly, the chimney can quickly collapse.

If the temperature of the flue gases is too low, condensation will form at the outlet of the chimney, and the outer part of the pipe will begin to freeze

If the temperature of the flue gases is too low, condensation will form at the outlet of the chimney, and the outer part of the pipe will begin to freeze In addition, the presence of constant condensation in the smoke channel leads to a weakening of natural draft. Therefore, it is so important to monitor the temperature of the flue gases, which directly depends on the cross-section of the chimney.

From the above we can conclude that with correct calculation, the temperature of the flue gases will be in the region of optimal values. If the temperature is too high and needs to be reduced, this directly indicates that the cross-section of the chimney does not correspond to the power of the gas boiler. To reduce the temperature of the exhaust gases, it is recommended to reassemble the smoke exhaust system taking into account the standard values.

Video: condensation in the chimney

How to check and adjust the draft in the chimney of a gas boiler

Draft is a decrease in pressure in the place where fuel combustion occurs. The pressure decrease occurs due to the removal of combustion products through the smoke channel. Speaking within the framework of this article, draft forces fresh air into the combustion chamber, where there is a reduced pressure that occurs due to the fact that gas combustion products are discharged outside.

The presence of draft indicates that the chimney is designed and installed correctly, and the equipment is working properly. The lack of draft may be a direct or indirect confirmation of the need for preventive maintenance or repair of equipment and the chimney system.

The speed of air flow in the chimney can be measured with a special device - an anemometer

The speed of air flow in the chimney can be measured with a special device - an anemometer The following methods are used to check the draft level:

- visual inspection - there should be no smoke in the room where the heating equipment is located;

- using improvised means, for example, a sheet of paper. It is brought to the inspection hole. If there is traction, then the sheet will deviate towards the hole;

- measurement with a special device - an anemometer. It is used to control air speed.

To control traction, it is better to use the latter method, since only it will show the exact value. When measuring natural draft, the flue gas velocity should be in the range of 6–10 m/s. The value is taken from SP 41–104–2000 “Design of autonomous heat supply sources.”

If it is necessary to reduce the draft level, then this will require reassembling the chimney based on a chimney of a larger cross-section. To increase traction, it is recommended to check the quality of the installation joints and mechanically clean the smoke channel using a steel cable with a brush attachment.

If this does not help, then the only way out is to replace the chimney with a preliminary calculation of the chimney cross-section. In this case, it is desirable to reduce the number of rotating elements to a minimum or remove them altogether.

Why does the boiler blow out and how to fix it

The main reason why the burner in a boiler blows out is the backdraft effect that occurs due to problems with the chimney.

Before starting any measures, you should check the height of the chimney above the ridge level and the presence of an installed deflector, which reduces the penetration of wind flows into the chimney. If the pipe installation is not carried out according to the rules, then after the steps described below, you will need to extend the pipe and install a deflector.

Sometimes, in order to increase draft, you need to clear the chimney of soot

Sometimes, in order to increase draft, you need to clear the chimney of soot In order to solve the problem with the boiler blowing out, you will need to do the following:

- First of all, you need to check the draft level in the pipe. It is better to use an anemometer. If you cannot find it, then with the boiler running you need to lean the paper against the outlet of the chimney. If the sheet is attracted to the chimney, then there should be no problems with draft.

- If you find that the blowing occurs due to a loss of natural draft, you will need to check the chimney joints. A thermal imager is used for this. If the pipe allows air to pass through, the device will show a strong temperature difference between the main pipe and the junction of the two modules.

- If the chimney is assembled correctly, then it is necessary to clean the smoke channel using a cable with a nozzle. The diameter of the nozzle is selected to match the cross-section of the chimney pipe. To remove soot, tar and other combustion products, an inspection hole is used at the bottom of the chimney.

- After completing these simple steps, you will need to check the traction level again. If natural draft has not improved, then it is necessary to carry out work to correct the height of the chimney and install a deflector. During installation, heat-resistant sealant and crimp clamps are used.

In cases where the work described above does not produce results, you should contact the gas service to check the gas equipment. Perhaps the problems with blowing are associated with hypersensitive automation.

Video: how to check draft in a gas boiler

Compliance with regulatory requirements is a guarantee that no emergency situations will arise during the operation of the chimney. This is especially true for vertical chimneys, when correcting errors made during their installation will require spending a lot of time.

Installing a chimney pipe, it is very important to calculate the correct chimney diameter, this issue needs to be given special attention when designing an autonomous heating system. Often the chimney pipe is selected based on approximate parameters. Many people believe that it would be better to make the cross-sectional diameter of the chimney larger, but this is not at all the case. In order for the heating system to function optimally, it is necessary to accurately calculate the diameter of the chimney.

Initial parameters for calculating the chimney pipe.

To calculate the chimney, you can use the chimney calculator.

The characteristics of the future chimney are directly influenced by certain parameters, of which the most important are:

1. Type of heating device. The organization of a gas exhaust system is in most cases necessary for solid fuel boilers and furnaces. The volume of the combustion chamber is taken into account, as well as the area of the opening of the chamber for air entering the firebox - the ash pan. Often calculations are made for homemade boilers that run on diesel fuel or gas.

2. The total length of the chimney and its configuration. The most optimal design is considered to be 5 meters long and with a straight line. Additional vortex zones that negatively affect traction are created by each turning angle.

3. Geometry of the chimney section. The ideal option is a cylindrical chimney design. But this shape is very difficult to achieve for brickwork. The rectangular (square) cross-section of the chimney is less efficient, but it will also require less labor.

Approximate and accurate calculation of the chimney diameter.

Accurate calculations are based on a complex mathematical platform. To calculate the chimney diameter, you need to know its main characteristics, as well as the characteristics of the fuel and heating device. For example, you can take the calculation of a standard pipe with a round cross-section without rotating units, connected to a stove and burning wood. The following calculation input parameters are taken:

- gas temperature at the entrance to the pipe t- 150°C;

- the average speed of gas passage along the entire length is 2 m/s;

- burning rate of wood (fuel) with one stack B = 10 kg/hour.

Following these data, you can proceed directly to the calculations. First you need to find out the volume of exhaust gases, it is determined by the formula:

Where V is the volume of air required to maintain the combustion process at a speed of 10 kg/hour. It is equal to 10 m³/kg.

Substituting this value we get the result:

Then we substitute this value into the formula according to which chimney diameter is calculated:

To make such a calculation, you need to know exactly all the parameters in the future gas exhaust system. This scheme is very rarely used in practice, especially in the case of organizing a household autonomous heating system. Determine the diameter of the chimney it is possible in other ways.

For example, based on the dimensions of the combustion chamber. Since the amount of fuel burned depends on its size, the volume of incoming gases also depends on it. If there is an open firebox and a chimney with a round cross-section, then the ratio is taken to be 1:10. That is, when the size of the combustion chamber is 50*40 cm, then the optimal chimney diameter will be 18 cm.

When constructing a brick chimney structure, the ratio is 1:1.5. Chimney system diameter in this case it must be larger than the size of the blower. The square cross-section will be no less than 140*140 mm (this is due to the turbulence created in the brick pipe).

Swedish method for calculating chimney diameter.

In the examples described above, the height of the gas exhaust system is not taken into account. For it, the ratio of the area of the combustion chamber to the cross-section of the pipe is used, taking into account its height. The pipe value is determined according to the graph:

Where f is the chimney area, and F is the firebox area.

However, this method is more applicable to fireplace systems, since the volume of air for the firebox is not taken into account.

You can choose different methods for calculating chimney diameter, but when installing complex heating systems, an optimally accurate design is important, especially for low-temperature long-burning heating devices.

Installation of boiler equipment and its efficient operation is impossible without a chimney.

The correct choice of materials and compliance with standards when connecting is the key to your safety.

Gas services strictly control the commissioning process and may fine violators or forcibly disconnect the user from the gas supply.

Basic requirements for materials:

- fire resistance;

- anti-corrosion properties;

- resistance to the effects of acid formed as a result of the interaction of condensate with combustion products;

- long period of use.

Brick chimney. It has low draft and is prone to rapid destruction due to the formation of abundant condensation on the surface, which turns into an ice crust during the cold season. Ideal only for fireplaces or as a kind of cover for a stainless steel chimney.

Stainless steel. It has a lot of advantages, which makes it one of the first in popularity among its peers. It has good traction, fire resistance and anti-corrosion, and a long service life (especially dual-circuit models). The modular assembly method allows you to create steel chimneys of different configurations and is accessible even to a non-professional. Compatible with high-power boilers. Will serve you for 15 years.

Chimneys made of galvanized steel behave much worse during use. Galvanization is susceptible to rust.

Service life – maximum 5 years.

Ceramic chimney. Externally, it is as massive as brick. The installation option is strictly vertical only. Austrian manufacturers have developed models of ceramic chimneys with an external contour not only made of ceramics, but also of metal. They are much lighter, but when installing them you need to calculate the loads on the foundation and walls. Warranty up to 30 years.

Asbestos cement pipes. Short service life (5 years), difficult to install, not environmentally friendly. Even the low price of the material cannot serve as a compelling reason to choose such a chimney. Overheating can simply rupture the pipe. Suitable for occasional use in the countryside.

Coaxial- made of aluminum in the form of two sandwich pipes with different diameters, located one inside the other. The external one is intended for supplying air, and the internal one is for removing combustion products. The structure is prefabricated. The location is most often horizontal.

Advantages of a coaxial chimney:

- Safety

- Increased efficiency of the heating system

- Environmental friendliness

Chimney elements

Regardless of the material, the design includes the following elements:

- Tee with revision— a fitting for condensate is installed at the bottom of the tee

- Adapter for connecting the gas boiler pipe and the chimney

- Fastenings- brackets and clamps

- Cone shaped tip

- Bends— installed no further than 2 meters from the beginning, otherwise the boiler draft is reduced;

- Feedthrough

- Telescopic pipes

Size Requirements

- Smoke channel should not contain ledges and be positioned strictly vertically. With a narrowed cross-section, a significant reduction in draft occurs, and when using pipes with a large diameter, it is possible to blow into the boiler chamber, with its subsequent attenuation.

- Sectional area of the chimney pipe should not be smaller than the area of the pipe through which the chimney is connected to the boiler.

How to calculate the chimney diameter

Key parameters- cross-sectional area (outlet F cm2).

The calculation is made using the formula F = (K ∙ Q) / (4.19 ∙ √ˉ N), Where:

K- coefficient calculated empirically (0.02-0.03);

Q- performance indicator of the gas appliance (indicated in the technical characteristics of the boiler);

N- chimney height.

The resulting number is adjusted by building codes and regulations.

For example, if brick is used, then the cross-section is 0.5 x 0.5 material.

For asbestos cement, the diameter is at least 10 cm.

Diameter of round chimney with a boiler power of 24 kW it should be 120 mm, 30 kW - 130 mm, 45 kW - 170 mm, 55 kW - 190 mm, 80 kW - 220 mm and 100 kW - 230 mm.

The minimum cross-section of rectangular channels depends on the thermal power of the boiler:

- Up to 3.5 kW - 14 by 14 cm.

- 3.5 to 5.2 kW - 14 by 20 cm.

- From 5.2 to 7.3 kW - 14 by 27 cm.

Design rules for boilers with natural removal of combustion products

- The chimney pipe must be located above the ridge of the roof, is at least 0.5 meters higher than it, provided that its axis is close to the ridge or parapet (less than 1 m and no more than 1.5 m).

- If the pipe is located further from the ridge (from 1.5 m to 3 m), then its height should be level with the ridge.

- When the chimney is located at a distance of more than 3 m, its height must not exceed the boundary of a line laid down from the ridge at an angle of 10° to the horizontal.

- If you have a flat roof, the height of your chimney should also have a minimum limit of 0.5 m, and in the case of a combined roof – 2 m.

A smoke removal pipe outside the building cannot be erected without insulation: the resulting condensate will destroy the chimney.

- The system for ejecting combustion products must be fixed to the wall at intervals of no more than 2.5 meters, in areas with a slope - every 1.5 meters.

- Clamp must be used on any connecting section of an insulated chimney.

- Chimney elbow must have a slope angle of at least 15 ° and no more than 90 ° (no more than three rotary bends in the system are allowed). The vertical section following the turn must be clearly secured with fastenings. It is prohibited to load inclined sections of the pipe or its bends.

- It is necessary to equip the chimney with a condensate drain, which must be available for service.

- The chimney must be insulated from flammable materials using brickwork or asbestos board. The distance from the connecting pipe to flammable surfaces must be at least 25 cm, and if a protective layer is applied - from 10 to 5 cm.

- Stable traction can be ensured, if you build a pipe above the wind pressure zone.

- Smoke exhaust systems built inside the building do not need to be additionally insulated, but it is necessary to take care of the tightness and ventilation system. Toxic smoke can easily seep even through the brickwork of the protective casing.

- Areas located outside the structure are insulated. In the absence of thermal insulation, the gases quickly cool, the draft decreases, and the boiler power drops. Condensation forms on the walls.

Requirements for installation of coaxial chimneys

When installing the smoke duct of such boilers, it is necessary to keep in mind that:

- When the length of the coaxial pipe is no more than 1 meter, it is necessary to install a tapering diaphragm on the air duct. The power of the fan in the chimney is designed for a certain pipe length and, if it is less, there will be a loss of draft with all the ensuing consequences.

- The pipe is located in a horizontal plane, but should still have a slope of 1 cm for each meter of total length and no more than two knees.

- Pipe head can protrude outward no more than the length of its tip - to protect against freezing, and not lower than 2 meters from the surface of the earth.

What do SNiPs say?

The installation of smoke ducts for gas boilers is regulated SNiP 2.04.05-91, and DBN V.2.5-20-2001

If you comply with all requirements during installation work, you can be sure that the gas service specialists will not have any questions for you. On cold winter evenings, your family will be warm and safe.

To learn how to choose and install a chimney correctly, watch the video:

The dimensions of the chimney greatly influence the efficiency and safety of the solid fuel boiler. The amount of thrust depends on them. If it is too strong, heat will also be released into the atmosphere in addition to carbon monoxide. The efficiency of the device will drop. Otherwise, the draft may overturn, that is, carbon monoxide will begin to escape through the ashpit. This is dangerous to the health of the residents of the house.

What can a chimney look like?

The smoke exhaust pipe can be made from various materials:

Each of these materials has a different thermal conductivity. The flue gases in the chimney are cooled differently, which affects the draft. This will be taken into account when calculating the height and diameter of the chimney.

The draft is also influenced by the cross-sectional shape of the chimney. It can be round, square and rectangular. The most convenient is the round shape.

Minimum chimney height

This indicator depends on the design features of the house and the height of adjacent houses or trees. There are 3 options:

- If the chimney is located no further than , then its height should be 50 cm greater than the entire height of the house. At a distance of 10 m from the bottom of the house to its top, the height of the chimney pipe used is Нт = 10+0.5 = 10.5 m.

- If the chimney is located at a distance of 1.5-3 m from the roof ridge, then its height can be equal to the height of the house.

- If the distance from the ridge is more than 3 m, then you need to use the formula Нт = П – D*0.1763:

- where P is the height of the house;

- D is the closest distance from the chimney to the line that descends from the ridge of the roof down the house (must be perpendicular to the horizon);

- 0.1763 – numerical expression tg(10°).

According to this formula, Ht = 10 – 3*0.1763 = 9.47 m.

Read also: Manufacturing a long-burning boiler with a water circuit

These three options are possible if there is no tall house or tree nearby. Otherwise, a chimney with a height of 10.5 m may fall into the wind pressure zone. This means that traction will be poor. In this case, you need to increase the chimney. To determine the amount of expansion, you need to find the highest point of the adjacent house and draw a conditional line from it so that it forms an angle of 45° with the ground. The top of the chimney should be above this line, since the entire space below it is a wind support zone.

Many manufacturers of solid fuel boilers sell plates in which the dimensions of the chimney and the amount of required draft correspond to a certain power.

Definition of traction

To do this, use the formula:

hc = H*(ρв – ρг):

- where H is the height of the chimney, starting from the smoke hole in the solid fuel boiler;

- ρв – air density;

- ρg – carbon monoxide density.

Formula for calculating ρв:

ρв = ρн*273/(273+t):

- where ρnu is the air density under standard conditions (equal to 1.2932 kg/m³);

- t is the outside temperature (it is better to take a temperature of +20 °C, since it is the worst operating condition).

For determining ρg you need to use special signs “Air density values that are given to operating conditions.” To do this, you need to find the average temperature of carbon monoxide in the chimney.