Such an important procedure as connecting a pumping station can be carried out according to various schemes, which makes it possible to pump out a liquid medium from different water supply sources. The choice of a specific connection scheme is determined by factors such as the water supply source used; number of water intake points; the number and type of household appliances that require water to function; the number of people living in the house; the presence of a garden plot (and therefore plants that need watering). After analyzing all of the above factors, you can select a specific model and begin connecting the pumping station according to a specific scheme.

What is a pumping station and what does it consist of?

A pumping station is a complex of equipment and technical means designed for supply, as well as for further transportation through a pipeline, of a liquid medium. The source of water supply to which such an installation is connected is usually a well (or well). Installing a pumping station in a country house or in a private house allows you to provide yourself with the required amount of water both for everyday needs and for watering the garden.

On the modern market you can find many pumping stations of various types and models. That is why it is important to know how to choose a device to solve certain problems, as well as how to install a pumping station in accordance with the chosen scheme so that such equipment operates with maximum efficiency.

Pumping stations, when compared with a separate water pump, ensure that the equipment operates in a more gentle mode, which significantly extends its service life. To understand how such installations work, you must first understand what structural elements they consist of.

So, the main structural components of pumping stations, used both to equip industrial enterprises and to solve everyday problems, are:

- a pump whose task is to pump out water (in the vast majority of cases, pumping stations are equipped with surface-type pumps);

- a hydraulic accumulator, which is a container, the inside of which is equipped with a membrane that separates the liquid medium pumped by the pump from the air;

- a control unit that ensures the operation of the pumping station in automatic mode, turning the pump on and off when the pressure level in the hydraulic accumulator reaches a certain value;

- control devices, the main one of which is a pressure gauge, which allows you to determine the pressure level in the water pumping station (WPS) system.

How to choose the right pumping unit

The question of how to connect the pumping station to a well or borehole is secondary. First you need to choose the right equipment. In this case, one must be guided by a number of factors.

Purpose

According to their purpose, pumping stations are divided into two main types: domestic and industrial. The latter, as their name implies, are equipped with manufacturing enterprises. The technical characteristics of these installations allow them to be used for pumping significant volumes of liquid media. Connection, adjustment, and especially installation of industrial-type pumping stations are carried out by qualified specialists.

Domestic-grade pumping stations are easy to install and easy to use

You can install a pumping station with your own hands if this equipment is intended to solve domestic problems (providing a summer house or country house with the required volume of water used for domestic needs, watering green spaces, organizing heating and operating washing machines, dishwashers, boilers, showers cabins, instantaneous water heaters, etc.).

Source type

A pumping station for a private home can be connected to various water supply sources. Each of them determines the scheme according to which the pumping station should be installed.

Operating mode

The connection diagram of a pumping station to a well, borehole or water supply system may imply manual or automatic mode. Depending on the required degree of mobility on the modern market, you can choose a stationary or mobile model.

When choosing a pumping station based on its operating mode and other parameters, one must also take into account how much water it must pump per unit of time. Thus, it is generally accepted that one person living in a private house needs 250 liters of water every day. When choosing a pumping station to equip a dacha, this figure can be reduced somewhat.

Installation location

Installation of a pumping station in a private house can be carried out in the basement of the building itself, in a separate building or in a caisson. The best of all the listed options is to install the station in the basement of the building it serves, where certain conditions are created for it.

So, in particular, it is necessary that the water supply pumping station, when installed in the basement of a house, be located at a level that will not allow it to be damaged when groundwater rises. In addition, it is necessary to ensure that the pumping station, which is installed in the basement, does not touch the walls with its body, which can lead to their vibration. It should also be borne in mind that the room in which the pumping station is installed must be heated. This will protect the equipment from freezing in water during operation in the cold season.

If you decide to use a caisson, then it must also be insulated, and the station itself must be located below ground level at a depth at which the soil no longer freezes. Thus, the depth at which the caisson is mounted must be at least 2 meters.

If the depth of the underground water source, for which the pumping station is used, does not exceed ten meters, you can opt for single-pipe models. If this parameter is in the range of 10–20 meters, you need to choose two-pipe pumping stations for a well or well, equipped with an ejector device. Before equipping an underground water source with such equipment, it is necessary to develop a scheme according to which the pumping station will be installed in a well or borehole.

If a separate room located on the territory of a personal plot is used to install a pumping station, then the problem with the noise that such equipment produces is solved, but access to it for maintenance and repair is difficult. This option also assumes that the room in which the pumping station will be installed is insulated. It is also necessary to ensure that the pipes through which water from such equipment is supplied to the water supply system of the house are reliably protected from freezing.

How installation is carried out according to various schemes

Connecting the pumping station to the water supply in the house, as mentioned above, can be carried out according to various schemes. In order for you to choose the best one, you should consider each in more detail.

Two-pipe connection

Connecting a pumping station to a well or well using a two-pipe scheme is carried out according to the following algorithm.

- The ejector is pre-assembled (for this you will need a cast iron tee with outlets for connections and a fitting).

- A mechanical cleaning filter is mounted on the lower pipe of the ejector.

- A plastic socket is installed on the upper branch pipe of the ejector, to which a fitting of the required length with a diameter of 1 1/4 inches is connected. To connect a given ejector pipe to a pipeline of a certain diameter, it may be necessary to use several connections.

- To connect the last flow to the pipeline, a coupling made of bronze is used.

- When placing the ejector in a borehole, it must be taken into account that the inlet pipe must be located at a distance of at least 1 meter from the bottom of the underground source, which will protect the device from large stones and sand getting into its interior.

- The length of the plastic pipe to which the ejector is connected before descending into the shaft is calculated as follows: one meter is subtracted from the distance from the bottom of the source to the mouth of the well.

- A pipe bend bent at an angle of 90° is installed at the upper end of the casing pipe. This homemade head is connected to the casing pipe using plumbing tape.

- The upper end of the pipe, which is connected to the ejector, is inserted into the socket of a homemade head and the space between the walls of the pipes is sealed using polyurethane foam. The second socket of such a head is connected to the outer part of the water supply using corner adapters.

- After carrying out the above procedures, it is necessary to connect a well pump with a hydraulic accumulator to the system, configure it to work with an ejector, and perform the first start of the pumping station.

You can learn more about what the above-described pumping station piping scheme looks like and how it is practically implemented using a video that is easy to find on the Internet.

When connecting a pumping station to a well with your own hands using a two-pipe scheme, you should avoid the typical mistakes listed below.

- When installing the pipeline leading from the pumping station to the house, the required pipe length margin was not taken into account.

- The threaded connections are not made very reliably and are poorly sealed, which can cause leakage of water supplied to the pipeline.

- No appropriate attention was paid to the hydraulic tank, which should ensure a pressure in the pipeline of at least one and a half atmospheres. If the pressure value is lower, then it should be increased by pumping air into the air chamber using a compressor or a simple pump.

Connection to the water supply system

The question of how to start a pumping station so that it pumps water from the main water supply most often arises in cases where the pressure is not enough for the heating system to operate efficiently. To properly connect the pumping station to the existing water supply, you must perform the following steps.

- At the place where the connection is planned, the water pipe is disconnected.

- The end of the disconnected pipe through which water flows from the central system is connected to the hydraulic tank.

- At the outlet of the storage tank, a pump is installed, the pressure line of which is connected to the pipeline leading to the house.

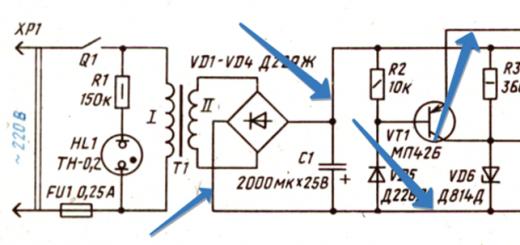

- Then the electrical part of the work is performed (connecting the power supply to the pump and performing a test run).

- Based on the test run results, the pumping equipment is adjusted and adjusted.

You can also get acquainted with the above-described process of connecting a pumping station in more detail using videos posted on the Internet.

It is very important to understand not only how to make the connection, but also how to adjust the pumping station, which is installed in a caisson, well pit or embedded in a central water supply system.

A properly adjusted set of such equipment should automatically turn off at a certain pressure (2.5–3 atm), and also automatically turn on when the liquid pressure in the system drops to 1.5–1.8 atm.

Both the installation of a pumping station in a well, borehole or a central water supply system, as well as its adjustment, can be done by yourself, the main thing is to know the algorithm for performing such procedures. After the borehole pump has been connected to the well, a pumping station has been installed in the well, or pumping equipment has been inserted into the central water supply system, you can proceed to adjustment.

In order to adjust the pumping station after connecting it and determine at what pressure value it will turn off and at what pressure it will turn on, about two liters of water are poured into the receiving device of the equipment, after which the pump is put into operation. When the station is turned off, the level of water pressure at which this occurred is recorded. In the same way, the pressure value at which the station automatically starts is recorded.

Fixing situations in which the pumping station does not turn off at a certain water pressure is quite simple. To do this, you need to adjust the operation of the pressure switch, the design of which for such purposes includes special screws that are responsible for the degree of compression of the springs. If the pumping station does not turn off when a certain water pressure is reached, it is necessary to adjust the pressure level at which the relay will operate. To do this, remove the device cover and tighten the screw with the letters DR in the “+” or “–” direction. To adjust the pressure level at which the station will automatically turn on, screw P is used.

Thus, knowing how to properly install a well pump with your own hands, this procedure is quite easy to cope with. Having information on how to connect a pumping station to a well, for the drilling of which it is better to involve qualified specialists, you can provide conditions for the most effective use of such equipment.

It is not always possible to use a centralized water supply, especially if the housing is somewhat remote from the city. But sometimes you have to connect special equipment, such as a pumping station for a home, the connection diagram of which depends on the operating conditions and parameters of the water source (well, well), and in conditions of insufficient water pressure from the central pipeline.

The most important, main components are the pump unit itself and the storage tank. Depending on the design, the mechanism is controlled by an automation unit or a float element. As a result, it turns out that each of the operating nodes is found in different versions. For example, the drive exists in the form of a hydraulic accumulator and a tank. The pumping unit itself may or may not be equipped with an ejector. Moreover, the first of these options can be made with a built-in or external ejector.

Devices with a storage tank have a long list of disadvantages, including the main ones: large dimensions, and therefore difficulties during installation, as well as the lack of forced action on water, which does not contribute to an increase in pressure in the system.

The most common versions today are those with a hydraulic accumulator.. The principle of their operation is based on the features of the main unit, which is divided inside the cavity into two compartments. Both of them are responsible for different functions: pumping air or water.

The pressure level is monitored by a relay, which turns off the device when the pressure reaches a certain level. If the value of this parameter drops to the minimum limit, the relay is activated and the device is put into operation. Despite its popularity, this type of equipment also has its drawbacks, in particular, the tank is not very spacious.

with hydraulic accumulator

with hydraulic accumulator Basic criteria for choosing a device

Installation of a pumping station in a private house is preceded by careful selection of the most suitable model. Among all the functions, including the least important ones, you should first of all pay attention to the following:

- the suction depth of the device, which must correspond to the parameters of the well itself, because if these parameters are met, as well as with sufficient power, the highest level of productivity can be obtained;

- water supply speed, also known as productivity;

- power of the device, but you should not choose a model with the largest margin for this parameter, as this will lead to unnecessarily high energy consumption;

- type of device control: manual drive or automatic;

- the number of people who will use such a water supply system in the future;

- tank volume, which will allow you to use the device for a long time without connecting to the mains.

If we talk about the performance of the device itself, then this parameter will never should not exceed the natural productivity of the water source(wells, wells). If these characteristics do not match, the liquid will be pumped with impurities.

A do-it-yourself pumping station for a dacha is connected based on some information about the composition of the family. So, if the power of the device is not sufficient to provide the required speed of pumping water, then there will not be enough water in the system to supply a large number of people living in the house, which will lead to a weakening of the pressure and uninterrupted operation of the device.

For example, in order for a family of 4 to be able to use a local water supply system, a device performance level of approximately 3 cubic meters is required. m/h, however, this figure may vary depending on the level of intensity of water use.

The principle of choosing a site for installation

The main disadvantage of pumping stations is the impossibility of using them during the cold season in unheated rooms or in open areas. It happens that users organize additional heating for devices standing on the surface of the earth, protected only by primitive construction. In this case, of course, there will be some effect from such actions, but in reality the result will only be excessive fuel consumption (if an liquid fuel heater is used, for example).

For more efficient and economical use of such units, before connecting a pumping station in a country house or in a private house, it is recommended to adhere to a number of rules:

- the location for installing pumping equipment should be chosen taking into account the possibility of installing a centralized heating system, and the presence of energy sources in the room is not desirable;

- It is recommended to organize free access to the device, which will simplify maintenance even in the event of equipment failure;

- professionals advise install such equipment as close to the water source as possible(well, well).

As you can see, if you plan to purchase such equipment, the connection diagram for a pumping station for a home or cottage from a well or should cover all possible features, up to the organization of a special room for these needs.

Choosing a system: one-pipe or two-pipe?

In total, there are two options for connecting equipment of this kind, each of which requires the need to take into account several parameters: the installation depth of the equipment, the configuration of the water supply. Thus, a distinction is made between one-pipe and two-pipe systems for connecting pumping equipment. In the first case, we are talking about shallow depths, while the second option is usually used to increase the depth of water suction by a pump from a well.

More specifically, some boundaries can be noted for both cases. For a one-pipe system, a threshold of up to 8 m depth is sufficient, for a two-pipe system – from 8 m or more. Moreover, the second option assumes use of pumping equipment with an external ejector.

How to connect to a water source (well, borehole)

Usually the location of the well is in close proximity to the home, which greatly simplifies the extraction of water and its supply to the house for the general needs of the family. Accordingly, you will not have to dig an endless trench to lay a pipeline, which is one of the main links in the chain of organizing local water supply using a pumping unit. Main works:

- Preparation of trenches, which are made at a depth below the soil freezing level and with a slight slope towards the water source to increase the efficiency of equipment operation and water supply to the site.

- Preparation of a polyethylene pipe with a diameter of 32 mm from a well (well) for connection with pumping equipment. At this stage, a check valve and a mesh are mounted on its end part. Moreover, installing a pumping station in a dacha with your own hands does not necessarily have to imply independent fastening of these elements, since it is quite possible to purchase a ready-made pipe with a check valve connected to it and a coarse filter (also known as a mesh).

- Connection to the pump unit is made using a coupling, a metal angle with a thread.

- Next, the pipe leading to the water supply is connected to the pumping equipment according to the principle described above, using a combined coupling with an angle of 90 degrees and an “American” one.

- Before the first start, water is first poured into the pump unit through a special hole.

A detailed connection diagram of the pumping station is shown in the photo.

Organization of connection to the water supply

When connecting a pumping station to a central water supply, connecting elements (fittings) are also used. A connecting element is attached to each of the holes (inlet and outlet), providing a hermetically sealed fastening of the pipeline. The pipeline from the pumping station is connected to the water supply using a special insert or tee.

For better water purification It is recommended to install two filter elements: coarse and deep cleaning. Moreover, there are some nuances when installing such parts. Before connecting to the internal water supply, a deep cleaning filter is installed, and a coarse filter element is mounted at the inlet of the pumping station. After fastening all the elements, the equipment is started.

Thus, in total, not much work needs to be done at the stage of connecting a pumping station for a summer house and home, but it is the preparation that takes more time, for example, digging trenches for laying a pipeline.

For greater convenience, some tricks are often used to smooth out the operation of such equipment, in particular, installing the pump on a concrete or brick base, on top of which a rubber mat is placed. In this case, the equipment is fixed to the base using anchors. This will somewhat smooth out the effect of vibration during operation of the device.

Additional information on how to install a pumping station at your dacha with your own hands is presented in the video.

Staying outside the city, in a country residence, has additional difficulties, since centralized communications are not available everywhere. Residents of the periphery improve living conditions in a cottage or house so that it does not differ from urban comfortable housing. One of the points of a comfortable life concerns the constant availability of water in sufficient quantities. In this case, special equipment will help - a do-it-yourself pumping station. By installing it yourself, you can save your family budget.

The majority of wells in summer cottages have a depth of up to 20 m – optimal for installing automatic equipment. With these parameters, there is no need to purchase a deep-well pump, an automatic control system or an intermediate tank: water flows directly from the well (or well) to the collection points. To ensure the correct connection of the pumping station, you need to understand what it consists of and how it works.

The main functional units of the station are the following equipment:

- , ensuring the rise of water and its transportation to the house.

- A hydraulic accumulator that softens hydraulic shock. It consists of two parts separated by a membrane.

- Electric motor connected to pressure switch and pump.

- A pressure switch that controls its level in the system. If the pressure drops below a certain parameter, it starts the motor, if there is excess pressure, it turns it off.

- A pressure gauge is a device for determining pressure. It is used to make adjustments.

- A water intake system equipped with a check valve (located in a well or well).

- The main connecting the water intake and the pump.

Using this formula, you can determine the maximum suction depth: the diagram clearly demonstrates what measurements need to be made for this

The most common version of a pumping station is a hydraulic accumulator with a surface pump mounted on top and a unit that includes a pressure gauge, pressure switch and dry-running protection

As can be seen from the table, the cost of pumping stations can vary. It depends on the power, maximum pressure, throughput, manufacturer

Before installing pumping equipment, it is necessary to purchase all functional parts according to the parameters of the well and water supply system.

Self-installation of a pumping station

At first glance, there are quite a lot of places for installing equipment - this is any free corner in the house or outside it. In reality, everything turns out to be different. However, only a well-thought-out installation of a pumping station guarantees its full operation, so some conditions must be observed.

Installation conditions:

- proximity to a well or well ensures stable water absorption;

- the room must be warm, dry and ventilated;

- the location should not be cramped, as maintenance and repair work will be required;

- the room must hide the noise produced by the pumping equipment.

One option for installing a pumping station is on a shelf specially attached to the wall. The installation room is a boiler room, boiler room or utility room.

It is difficult to comply with all the conditions, but it is advisable to adhere to at least some. So, let's look at several suitable installation locations.

Option #1 – room inside the house

A well-insulated boiler room on the territory of the cottage is an ideal area for installation in case of permanent residence. The main disadvantage is good audibility with poor sound insulation of the room.

If the pumping station is located in a separate room of a country house, then it is best to install the well directly under the building

The material on how to make a well water supply system will also be useful:

Option #2 – basement

An underground or basement room can be equipped for the installation of a pumping station, but this should be considered during the design. If there is no heating in the room, and the floors and walls are not insulated, you will have to spend a lot of effort to prepare it.

A well-equipped basement is ideal for installing a pumping station. When laying a pipeline, a hole for communications should be made in the foundation of the house.

Option #3 – special well

A possible option that has a couple of pitfalls. The first is the difficulty of maintaining the required level of pressure in the house, the second is the difficulty of carrying out repair work.

When the pumping station is located in a well, on a specially equipped site, the pressure level should be adjusted, which depends on the power of the equipment and the parameters of the pressure pipe

Option #4 – caisson

A special area near the well exit is also suitable for installation, the main thing is to correctly calculate the depth of its location. The required temperature will be created by the heat of the earth.

The pumping station located in the well caisson has two advantages: complete noise insulation and protection from freezing during frosts

In the absence of specially designated places, the unit is installed in common areas (in the hallway, bathroom, corridor, kitchen), but this is a last resort. The loud noise of the station and comfortable rest are incompatible concepts, so it is better to prepare a separate room for installing a pumping station in the country.

Pipeline laying

The well is usually located near the house. In order for the pumping station to operate properly and without interruptions, it is necessary to ensure the unhindered flow of water from the source to the equipment, which is located in a specially designated area. For this purpose, a pipeline is laid.

Low winter temperatures can cause pipes to freeze, so they are buried in the ground, preferably to a depth below the ground freezing level. Otherwise, the line should be insulated. The work boils down to the following:

- digging a trench with a slight slope towards the well;

- installing a hole in the foundation for the pipe at the optimal height (if necessary);

- pipe laying;

- connecting the pipeline to pumping equipment.

During the construction of the highway, you may encounter a problem such as the presence of high-standing surface water. In this case, the pipes are installed above the critical level, and heat-insulating material or a heating cable are used to protect against cold.

Advantages of polyethylene pipes and fittings over their metal counterparts: lack of corrosion, ease of installation and repair, low price (30-40 rubles/linear meter)

This pumping station installation diagram shows an option for insulating pipes above the ground freezing level

The best option for thermal insulation of external water pipes is a solid “shell” of polystyrene foam (8 cm thick) wrapped in foil

For thermal insulation of pipes that are laid above the ground freezing level, an inexpensive and environmentally friendly material is often used - basalt-based mineral wool.

Exterior works

We attach a metal mesh to the outside of the polypropylene pipe, which will serve as a coarse filter. In addition, you will need a check valve to ensure that the pipe is constantly filled with water.

It is possible to purchase a ready-made hose with a check valve and a coarse filter, but equipped with your own hands will cost much less

Without this part, the pipe will remain empty, therefore, the pump will not be able to pump water. We fix the check valve using a coupling with an external thread. The end of the pipe equipped in this way is placed in the well.

The coarse filter for the supply hose is a metal mesh with a fine mesh. Without it, proper operation of the pumping station is impossible

After completing these steps, you can start upgrading the well head.

Connecting equipment

So, how should you properly connect your home pumping station so as not to encounter technical inconsistencies in the future? First of all, we install the unit on a specially prepared base. It can be brick, concrete or wood. To ensure stability, we screw the legs of the station using anchor bolts.

For installation of the pumping station, special legs-stands are provided; however, to provide additional stability, the equipment must be fixed with bolts

Placing a rubber mat under the equipment can help dampen unnecessary vibrations.

For more convenient maintenance, the pumping station is installed on a base the height of a regular table, made of durable material - concrete, brick

The next step is to connect the pipe coming from the well. Most often this is a polyethylene product with a diameter of 32 mm. To connect, you will need a coupling with an external thread (1 inch), a metal angle with an external thread (1 inch), a check valve with the same diameter, and a straight American tap. We connect all the parts: we secure the pipe with a coupling, and we fix the “American” with a thread.

One of the check valves is located in the well, the second is mounted directly to the pumping station. Both valves serve to protect the system from water hammer and ensure the correct direction of water movement

The second outlet is intended for communication with the water supply network. It is usually located at the top of the equipment. The connection pipes are also made of polyethylene, as it is an inexpensive, flexible, durable material. Fixing occurs in a similar way - using an “American” and a combined coupling (1 inch, 90° angle) with an external thread. First, we screw the “American” to the outlet of the station, then we install a propylene coupling into the tap, and finally we fix the water pipe in the coupling using the soldering method.

To completely seal the connections, they must be sealed. Traditionally, a winding made of flax is used, and a special sealing paste is applied on top of it.

After you have connected the pumping station to the water intake and plumbing system, you need to check the quality of its operation.

We are conducting a test run

Before starting the station, it must be filled with water. We let water through the filler hole so that it fills the accumulator, lines and pump. Open the valves and turn on the power. The engine starts and water begins to fill the pressure pipe until all the air is removed. The pressure will increase until the set value is reached - 1.5-3 atm, then the equipment will automatically turn off.

In some cases it is necessary to adjust the pressure value. To do this, remove the cover from the relay and tighten the nut

As you can see, installing a home pumping station with your own hands is not at all difficult; the main thing is to follow the installation instructions.

Comfortable and complete living in a country house without running water is impossible. Today, country houses have not only water intake taps, but also equipment that requires automatic water supply. Pumping stations are installed to supply water around the clock.

Scope of application

When a water supply structure is being built, any owner wants to end up with constant water pressure. Pumping stations are designed to lift water from depths from wells and wells. There are many models of pumping equipment on the market, differing both in power, location and principle of operation. Surface systems are placed on the ground, and water is supplied using a hose; submersible structures are lowered into a well or borehole.

If the pump is used around the clock in a constant mode, then the structure will wear out very quickly, and this is where a pumping station is used to constantly supply water.

Construction of pumping stations:

- Pump. This type of equipment uses surface pumps;

- Filter;

- Hydraulic accumulator. The principle of operation of the battery is based on stretching the rubber partition when the pressure increases, and vice versa when the pressure decreases. Thereby stabilizing the pressure;

- The pumping system is equipped with a control unit to determine when it is necessary to turn the equipment on and off.

Options for installing a pumping station for a private home

There are several options for installing pumping equipment, regardless of the location of the source:

- In the basement of the building. This method greatly facilitates system maintenance, since there is free access, but you should think about it before installation, since some types of pumping stations are very noisy;

- Can be located in a buiding, standing separately near the well, but this will require additional construction costs;

- In the caisson– this location occurs below soil freezing.

How to choose a location?

Pumping equipment emits strong vibrations; the base on which the system will stand must be firmly and securely fixed. Otherwise, vibrations may result in leaks at the joints of the water supply system, and the structure should not come into contact with the walls.

The system must not be exposed to frost; the room must be heated; sub-zero temperatures will damage all parts.

Options for connection diagrams of a pumping station for a private house

There are two installation schemes: two-pipe and one-pipe; the choice will depend on the design of the water supply system. A two-pipe design is used if it is necessary to supply water from a great depth of more than 20 m. A single-pipe design is used at a depth of less than 10 m.

Two-pipe connection

First, the ejector is assembled; there are 3 outlets for connecting the water supply.

- The mesh filter is installed on the bottom of the ejector; if sand and small debris from the well get into the system, it will protect against damage;

- The socket is installed on the upper part, and then the squeegee is installed. It may be necessary to attach several bends to achieve the required cross-section;

- The coupling is mounted at the end of the flow, it will serve as a transition to the water supply.

It is necessary to ensure that the entire structure of the system and its joints are sealed, since if air is taken in, the equipment may begin to function unstably and lose significant power. Using fum tape, gaskets or specialized paste, threaded connections are securely fixed.

During the process of placing pipes in place, you need to take care of some reserve. After laying the pipes, start connecting:

- The head is mounted on the casing;

- Using any long object, the immersion depth of the pipes is calculated. The inlet pipe should not reach the bottom of the well by about 1 meter;

- Polyethylene pipes are mounted to the ejector structure;

- An elbow is mounted on the well head;

- Plastic pipes pass through the elbow. When laying pipes, they can be connected by adapters or be bent;

- The ejector structure is lowered to the required depth;

- The head is fixed to the casing using reinforced tape.

Pipes are laid to the house; they pass through the foundation below the soil freezing level. Afterwards, pipes are connected to the water pipe of the pumping station, everything is fixed with an adjustable wrench.

You cannot run the pump dry; you need to pour water into the upper hole of the pumping station; this procedure must be performed once. After the first start-up, the pressure is checked; according to average indicators, it should be 1.5 atmospheres. If necessary, these figures can be increased using a car pump.

After installing the pumping station, the equipment is started in test mode and the functionality of the system is checked.

Common mistakes when installing a pumping station

When installing a pumping station yourself, as a rule, four main mistakes are made:

- If increased water consumption occurs, the pressure in the system decreases sharply;

- If any kind of error occurred during installation: frequent switching off and on. The hydraulic tank must control the frequency of switching on and the fluid level, but this does not happen in all cases;

- The electric motor of the pumping station may fail due to power outages; a backup power source can solve this problem. Circuit breakers and stabilizers are needed if frequent surges occur in the voltage network;

- An incorrect choice of pumping device power or an error in calculating the depth of the well can lead to breakdown of the entire unit, since if the filter is damaged, sand will enter the system.

If the installation procedure was carried out correctly, the pumping station will serve its owners for about 7 years without interruptions or breakdowns; experts recommend that in order to save effort and time, it is better to immediately seek professional help.

One of the first engineering systems that are created in private households is water supply. Its use is necessary at the construction stage. Without a plumbing system, it is impossible to fully live in a house around the clock. Modern houses have as part of their engineering networks not only ordinary water taps, but also automatic devices that use water. In order to have water pressure in your home around the clock, each owner needs to know how to connect a pumping station.

What is a pumping station?

When building an autonomous water supply system and connecting the water supply of a private house to the main utility networks, each owner wants to receive a constant water pressure in the system. So, to lift water from a well or from a well located on a personal plot, you can use pumping devices. They come in different models and capacities and can be located in different segments of the water supply system. Submersible pumps are lowered directly into a well or well, while surface pumps are placed at ground level, drawing water through an inlet hose.

The pump should not run continuously. Continuous operation leads to rapid wear of the components and mechanisms of this device. At the same time, do you want to use water at any time of the day? There is a solution: to ensure constant pressure in the pipelines of the water supply system, a pumping equipment station is assembled.

Main parts of the pumping station

- N asos. Typically, a set of stations uses surface pumps, which draw water from a well, borehole or main network through an inlet pipe with a filter.

- Pressure accumulator or hydraulic accumulator. It is usually a container of a certain size, inside of which there is an elastic rubber partition or inner container. When the pressure increases, the system container or partition expands, and when the pressure decreases, it contracts, squeezing water into the system and maintaining constant pressure parameters.

- Control node, which determines when the pumping device starts and when it stops working. The on and off parameters are determined by the pressure in the system, which is measured by a pressure gauge.

Prices for a pumping station

pumping station

Options for installing a pumping equipment station

Pumping equipment stations, regardless of the location of the water source, can be installed in three main places.

Features of choosing a location for a pumping station

Connection options for pumping equipment station

Depending on the configuration of the water supply system, you can choose one-pipe and two-pipe connection schemes for the pumping equipment station. A two-pipe system is used to increase the depth from which a pumping station can lift water.

The single-pipe scheme is used for well depths not exceeding 10 meters. If it exceeds 20 meters, then it is preferable to use a two-pipe circuit with an ejector.

Connecting a pumping station (two-pipe scheme)

At the initial stage, an ejector is assembled, which is a separate unit made of cast iron with three outlets for connecting a pipeline.

- First, we install a filter mesh on the ejector (in its lower part), which protects the pumping equipment from failure when small stones or sand enter from a well or well.

- A plastic socket is mounted in the upper part of the ejector assembly, to which a squeegee with a cross-section of 3.2 cm is attached. You may have to mount several squeegees at the same time in order to reach the cross-section of the water pipe.

- At the end of the run, we install a coupling that will ensure the transition to a plastic pipeline. Typically such a coupling is made of bronze.

When connecting elements, pay special attention to the tightness of the connections. Of course, a leak in a well or borehole will not cause you any aesthetic inconvenience, however, air intake in leaky connections can lead to instability in the operation of the system and a significant reduction in its power. Threaded connections are sealed with a special paste, fum tape, linen winding or rubber gaskets.

Remember! Water supply pipelines must either pass below the soil freezing depth or be properly insulated.

When introducing water supply pipes into a caisson or another location where a pumping equipment station is installed, it is necessary to provide them with some reserve in length. After removing the pipes, we begin to connect the pumping equipment station to the pipelines from the well.

- We install the head on the casing pipe of the drilled well.

- We find out the depth of lowering the pipes into the water well. To do this, lower any solid long object into the drilled shaft. The level of placement of the inlet pipe of the pumping equipment station should be approximately a meter away from the bottom of the well, so as not to suck in sand, silt or stones from the bottom.

- We attach polyethylene pipes to the ejector unit. The length of the pipe should be equal to the sum of the distance from the wellhead to the pump and the depth of the well (minus one meter).

- We mount an elbow at the well head with a 90-degree rotation.

- We insert plastic pipes leading to the ejector unit through the straight elbow (after installation is completed, the space between the inside of the elbow and the pipelines can be filled with foam). In a straight elbow, the pipes can be either bent or connected by adapters with a rotation angle of 90 degrees.

- We lower the ejector device to the required depth. You can check the correct installation depth of the ejector using the mark we previously made on the pipeline.

- We fix a homemade head on the top of the casing, which consists of a pipe bend turned at an angle of 90 degrees. You can secure the “head” to the well casing using specialized tape for plumbing fixtures with reinforcement.

We bring water pipes to the house. You may have to provide turns. The entrance of water pipes through the foundation must be located below the soil freezing line. The removed pipes are connected to the water pipe of the pump as part of the station. The pipelines are connected using a wrench or an adjustable wrench.

There is usually a filler hole on the top of the pump as part of the equipment station. It is necessary so that it does not start “dry”. Filling with water is carried out only during the initial start-up or when starting up after a long period of inactivity.

Before starting the pumping equipment station, check the operating pressure in the hydraulic accumulator. Usually it is 1.2 - 1.5 atmospheres. You can increase the operating pressure using a regular car pump. For pumping up pressure accumulators in water supply systems there is a special nipple.

How to connect a pumping equipment station to the main water supply

Sometimes it is necessary to connect a pumping equipment station not to a well or well, but to the main water supply. This is relevant when connecting to utility networks with low or unstable pressure. You can make such a connection in the following sequence.

We regulate the operation of the pumping equipment station

After installing the connecting elements, the system must be run in test mode to check the tightness and functionality of all its segments. Before starting, water is poured into the filling hole of the pumping equipment station, this prevents the device from running dry.

As a rule, all adjustment parameters are set at the station before it is launched, based on the calculated parameters of the house’s plumbing system. During operation, the working components of the pumping equipment station may wear out, so it is advisable to carry out additional adjustments of the pump operating parameters approximately once a year. Precise adjustment of the pumping equipment system with built-in pressure accumulators is carried out by its own automation unit.

An important nuance. All pumping equipment stations incorporate an electric motor. It may have more power, so we recommend that you provide such a station with its own power supply line. The power line of the station will operate in a humid environment, so take care to install protected sockets and lay cables in special corrugated tubes.

As you can see, connecting a pumping equipment station is accessible even to a non-professional with minimal technological skills. Its installation will help you ensure uninterrupted water supply to your home and garden.

Video - How to connect a pumping station