There are ready-made projects, but they often do not satisfy all needs. Such oven, ordering which has already been designed, often requires modification. The change in order must be recorded in the project with an accurate drawing of each row of brickwork. To be 100% sure, after adjusting the project, you need to show it to a specialist and agree with him on all the nuances of the future furnace.

Finished stove project

The main rule that must be taken into account when designing a furnace is the safety of its operation, so consultation with a specialist is a necessary measure.

When making amendments and changes to the finished project, you should take into account the construction features:

- the firebox in the heaters should be large;

- the grates are laid along the blower part of the furnace;

- when constructing a heater raised on top of the firebox, it is necessary to ensure the height of the firebox is equal to approximately nine rows of brickwork;

- the distance between the stove and other bathhouse furniture made of wood must be at least 35 cm;

- each row of masonry is checked using a building level;

- the masonry begins from the installed stove doors;

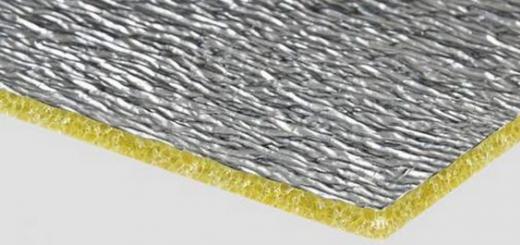

- The stove chimney in the section between the heater and the roof must be covered with a heat insulator.

When building a firebox, you should take into account its purpose - ensuring good combustion. For normal operation it is necessary to ensure sufficient air flow. This is facilitated by the large size of the firebox. For the same reason, the blower should also be large in size.

Large grates provide the necessary air flow, but they are often difficult to select. The way out of this situation is to install several fire bars.

The height of the firebox should be at least 50 cm, that is, about 9 masonry. This will ensure even heating of the bricks. If the height of the firebox is smaller, the temperature of the bricks will drop, and soot will constantly accumulate between them.

Starting the laying from the doors, you need to stock up on strips or asbestos cords for winding that part of the door that is adjacent to the brickwork. In this part, the masonry is secured using strong wire to secure the seams. To ensure the necessary rigidity of the structure, it is recommended to lay special grooves or grooves into which the wire will lie.

Below is a visual example of a project in which a tank that heats water is in direct contact with a heater. This allows for additional heating from the chimney.

Furnace design with a tank located on the side

The heater's container has dimensions of 53x51x50 cm; sheet steel 8-9 mm thick was used in the manufacture of the container. To make the tank, a pipe with a cross section of 400 mm was used. This container can hold about 50 liters of water. A frame made by welding from corners was used as a support.

The design features of this stove are the lid, when opened, stones are placed inside and liquid is filled on top. When the lid is closed, the stones will heat up as much as possible, and if you open it or open it slightly, the heating temperature of the stones will decrease.

After the heater is installed on the welded frame, it should be covered with bricks. For convenience, the bricks are laid edgewise.

Below is a design option for a closed heater with a tank installed on the side.

Closed heater with tank

As you can see from the figure below, the order is extremely simple and easy to do.

Do-it-yourself brick sauna stove: ordering

To heat a steam room designed for four people to steam at the same time, you can use the projects presented below.

Furnace placement

This stove with a closed heater is not small in size. Features of operation are that the stones are loaded into the heater only after the stove is completely dry.

This design is called a continuous stove, which means it can be lit even if there are vacationers in the room. The special design developed by A. Zabolotny is absolutely safe, since during heating no combustion products are released into the room.

Another feature of such a stove is the possibility of installing ventilation for the subfloor of the bathhouse. This will extend the service life of the room and protect the floor from moisture. For this, a regular corrugated hose is usually used.

Brick oven by A. Zabolotny

To build such a furnace, you need to stock up on:

- bricks for masonry (approximately 700-800 pcs);

- fireclay bricks in the amount of 35-45 pieces;

- thirty buckets of sand;

- clay in the amount of 200-250 liters;

- doors and sashes for ovens

- corners for making a frame base;

- grates.

In order for the heater cabinet in which the stones are placed to withstand high temperatures normally, it should be made of high-quality stainless steel. To give the structure the necessary rigidity, stiffeners should be welded along the side walls. Such DIY brick oven, the order of which is shown in the figure below, is easy to construct and is highly reliable and safe.

Furnace order

For masonry you should use the following algorithm.

- The beginning of the masonry begins with the construction of a ventilation duct for the steam room. The scheme must be followed with precision. To determine the correct placement, you should periodically check the level of the masonry for compliance with the horizontal and vertical surfaces.

- A damper should be installed in the third row of masonry. This is where the fireboxes are formed and their doors (doors) are mounted. In the next row, it is necessary to block the damper with a channel, which will be used to cleanse accumulated soot. In the fourth row, a door for this channel is built, with the help of which cleaning will be carried out.

- It is necessary to close the blower flaps in the next, fifth, row of masonry. Also in this row it is necessary to install metal jumpers, about three millimeters thick.

- In the sixth row, separation is carried out using grates. Also here it is necessary to line the firebox shaft using fireclay bricks. For masonry you will need a special mortar intended for the construction of a firebox.

- Under the gratings you need to go deeper into the brick. This will allow you to maintain a gap if thermal expansion is necessary.

- For the construction of chimney channels, it is necessary to use strips of reliable metal laid in bricks.

- The seventh row is placed to install the firebox doors. For this, fireclay bricks laid on the side are also used. Simultaneously with the masonry, it is necessary to install the firebox doors themselves.

- In the eighth row, the masonry should be continued on the side of the firebox flaps.

- In the ninth row of masonry, the doors are covered with strips of metal, which will also serve as support for the floor bricks.

- Next, you need to line the doors on top with bricks. If necessary, for a denser masonry, the bricks can be sawed down.

- 1In the eleventh row, it is necessary to lay a slab platform above the first shaft, and above the second shaft, a fireclay brick laying is used on the smaller side of the firebox. In the future, when a container for stones is installed, chimney channels will be built in this part.

- Next, you need to install a metal box to place the stones in it. Also in this row one chimney channel is laid.

- In the next few rows, the masonry is carried out as a continuation of the previous rows.

- In the fifteenth row of masonry, a sash should be installed through which soot will be removed.

- In the sixteenth row above the shaft it is necessary to mount jumpers.

- The next row is characterized by a branching into two chimneys, just as it was done in the fifth row. To begin the next row of masonry, it is necessary to install lintels above the chimney shaft slab. These lintels will serve as a support for laying the next rows.

- In the eighteenth row, it is necessary to mount the chimney flap, and in the next row, metal jumpers should be mounted on the other side of the heater. These lintels are necessary for laying the ceiling and building the vault of the heater.

- In the twenty-first row, it is necessary to continue the masonry, taking into account the chimney ducts. In the following rows there is a narrowing of the volume of the shaft, and in the twenty-fourth row the shaft in which the reservoir for placing stones is stored is finally closed.

How the chimney is built and formed is shown in the figure below.

19. Starting from the twenty-fourth row of masonry, it is necessary to block another fuel shaft, and starting from the 27th row, the chimney is blocked.

Small brick oven

In a small steam room there is no need to install a large stove. To do this, it is enough to build a small stove that will effectively heat the steam room.

The advantage of the furnace shown in the figure below is its ease of construction and cost-effectiveness.

Small sauna stove project

The procedure for such a stove is extremely clear and simple. This furnace can be erected without a foundation, subject to all fire safety measures. The stove is lightweight, so construction is quick and easy.

The network is full of materials that suggest, without any preliminary planning, disassembling the elements and their connection in a system called a “sauna stove,” to immediately begin laying it. This only means that the people who wrote are extremely far from practice, and their advice contains a mixture of useful information, heresy and silence on essential issues.

We will take a different route: without directly touching on the issue of independent masonry, we will tell you what professional stove makers know about.

Brick stove for a bath

Let's start with the fact that amateurs choose a brick heater for a bath specifically Russian steam room, because . There is a lot on our website, so for now it’s enough to say that a closed heater is one of the important conditions, working together:

- brickwork;

- a container for stones, closed on all sides, placed inside the oven;

- controlled convection (the ability to almost completely block air flows).

However, in the baths you can also find open heaters. This is not entirely “according to the rules,” but this option is not a remake. Quicker, this is an echo or descendant of “black-style” sauna stoves.

However, in the baths you can also find open heaters. This is not entirely “according to the rules,” but this option is not a remake. Quicker, this is an echo or descendant of “black-style” sauna stoves.

The main problem with an open heater is that it freely gives off heat to the surrounding air, not allowing this process to be regulated. In addition, the top row of stones never heats up to the temperature of producing light steam, so in cases of open heaters it is necessary to “extract” it using steam gun, supplying water to the most heated stones at the bottom of the laying.

We will not consider an option that is less consistent with our concept of a Russian bath, so we will immediately move on to the “proper stove”:

With closed heater

Brick deserves special consideration. The designs of brick stoves are quite diverse, in particular, they can be inherited from conventional heating stoves smoke circulation system, which allows you to significantly reduce the temperature of the furnace gases escaping into the chimney pipe, accumulating heat in the furnace mass.

However, placing a stone filling inside a brick stove-heater makes it possible to no less effectively remove heat from the furnace gases passing through it or flowing around it (depending on the design).

Thus, the simplest option for implementing a brick stove for a bath with a closed heater is direct-flow stove without smoke circulation. Which is not without its advantages, because it saves the owner from the need for more complex cleaning than in this case.

The stove consists of a firebox, above which there is a stone backfill in a flow-through heater, and a chimney. The density and mass of the backfill are such that the furnace gases lose not only heat, but also sparks, and only smoke goes into the chimney.

IMPORTANT! It is recommended to place stones in such a stove at the rate of 15 kg per cubic meter of steam room, but this is the minimum value. Optimal – 40-50 kg. At the same time, you don’t need to worry about volume - the stones are heavy, they have a high density (1600-1800 kg/cube), so they don’t take up much space.

It also wouldn't hurt lining. Moreover, it is advisable to cover not only the inside of the firebox with fireclay bricks, but also the heater. The main advantage of the lining is increasing the service life of the furnace.

Another means for the same thing is metal strips and corners, which tighten the lining, and, if desired, the stove itself from the outside.

As for choosing the shape of the stove base, it can be square or rectangular. Based on the geometry of the brick, a rectangular shape will be better, because then you won’t have to cut the brick. However, there are also square designs where you don’t have to cut almost anything.

With or without a blower?

Now about the blower. If a brick stove is being built for a bathhouse, is there a need for a vent in it? Let's first explain what it is blower. This is a kind of channel that brings air under grate, and through it - into the firebox, supplying the fuel with the oxygen necessary for its combustion. A door is used to regulate the intensity of air flow (draft).

Traction exists when there are two holes - at the bottom of the stove and at the top of the chimney. That's why their sizes are related to each other. In addition, there is a certain relationship between the volume of the firebox and the draft - if the draft is too strong, the wood will burn quickly and at a higher temperature.

When installing a brick stove for a bathhouse, you can refuse the blower and put the deaf under. This doesn't mean you won't have any cravings at all. It will be due to the slightly open fire door. In principle, the stove will work, but the dimensions of the combustion door are large enough to allow fine adjustment of the air supply. At the same time, the efficiency of the stove becomes lower than it could be.

But this is not the only argument against a blind hearth. It will be a big punishment for the owners danger of burning embers falling out when the door is open, as well as the need frequent use of a poker, because firewood never burns out completely. Upon completion of the combustion process, you will need more pull out the firebrands and immediately simmer them in a bucket of water.

If we talk about the sufficient dimensions of the grate and the cross-section of the chimney pipe, then both can be approximately equal area of one standard brick. This is enough for normal traction.

As for water tanks, when making it yourself, it is not recommended to use materials such as black And Cink Steel. Stop choosing instead. either tinned copper or stainless steel.

What do stove makers say about brick? They say that there is no alternative nowadays red, full-bodied, produced by wet pressing. Of course - with the correct geometry, without changes in color, indicating non-uniform firing. And also loud, like metal, sounding when you hit it. Under-burning is manifested by pallor of color, and overburntness can only be seen at the break - there will be blue-black areas.

As for the pipe, from the moment it passes the roof, it is better to cover it clinker bricks, but you also need to be able to choose it. The reason is increased frost resistance - 70 or more cycles.

Attention! Clinker is not suitable for laying the stove itself, because it has weak adhesion to the mortar - it does not take water.

Fireclay brick used only for construction fuel core, which can also be considered as the lining of the firebox. In the case we described, the lining was also made for the heater.

Important! Red brick is placed on a regular mortar of clay and sand, and fireclay brick is placed on a mixture of fireclay with fireclay chips. Pipe above roof level - mortar without clay, cement-sand or cement, sand, lime.

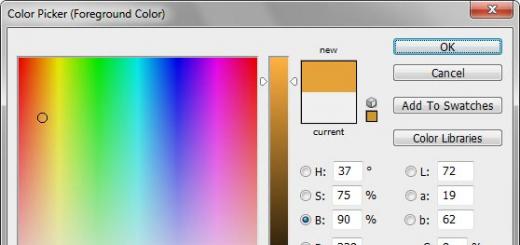

For one part clay is taken from 1 to 6 parts sand, but here it all depends on the fat content of the clay itself; the more it crumbles when drying, the less sand it needs. Oily clay It doesn't crumble, it cracks. Normal solution It doesn’t crack, and if it crumbles, it’s only along the edge. Usually, to calculate the proportion, samples are made with different proportions of sand and dried.

Advice! If possible, take it quarry or mountain sand- he is the best.

The bricks are counted simply: according to the masonry drawings, and the height of one row with mortar is 7 cm. When lining a pipe, the number of bricks in a row is also multiplied by the number of rows in height, plus 50 pieces for fluff (fire expansion) and 70 for the head and otter. All that remains is to calculate the number of cubic meters, but this is also simple: we proceed from the fact that there are 420 bricks in one cube. When purchasing, you should add another 10% on top of the amount received.

Brick stoves with heater and tank

A tank is not an indispensable attribute of a sauna stove, but for those who have problems with hot water, it becomes a very relevant addition.

You just need to take into account the following things: the stones in the heater must warm up degrees up to 300, so that you can get light steam from them. And the water is higher 100 degrees It just can't get warm. What does it mean? What if we place the tank side by side with the heater, the water will significantly cool the stones and prevent it from achieving the desired temperature.

And here we have two options: either design the stove so that the heater and the tank do not touch at all, or let the stones heat up first, and place the tank above them next to the pipe. There is also a third option: heat the water using a heat exchanger coil (discussed separately), which is located inside the firebox, heating the water in an external tank by natural or forced convection.

Brick heater for a bath, options for placing a water tank

It is clear that When the tank is located on the side, it is more convenient to fill and empty it, if there is no cold water supply network, that is, manually, but this will have to be done more than once or twice while the oven is heating, because the water will boil quickly.

For those who try to “solve the problem” by will increase the tank volume, we have to say that the idea is not so good - the water takes heat away from the stove, and the more it is, the more you will reduce the efficiency of the stove. Moreover, even having reached the boiling point, it will still take away heat, because the temperature inside is much higher.

The only thing that can be suggested in this situation is to design in which the tank will be as close as possible to the fire door. This way you can reduce the heat a little.

If you choose over the heater, then only if there is cold water supply. Because you'll get tired of carrying water upstairs.

However, she really good from the point of view of increasing efficiency– the water will take heat away from the pipe and from the top of the heater.

On a note! Water can be supplied to the tank under pressure, which forces you to take care of two things: you will need fuse (burst valve), which relieves excess pressure, and will also need screeds inside the tank.

But if pressure occurs only when water is supplied to the tank, then you can forget about the above. But you may need overflow pipe.

The tank should not be placed on bare brick. Pros advise taking a sheet of asbestos or basalt cardboard and soaking it in a clay solution. Then you place the soaked sheet on the bricks, and place the tank on top. On top of the tank is another sheet of the same type. On it - foil and some kind of non-flammable thermal insulator - mineral wool, expanded clay, foam glass...

By the way! When the fuel core on which the tank will be installed has already been laid out, there is no need to rush to install it. We have to wait Couple of weeks, which the masonry needs to dry sufficiently. Only after this can the tank be placed on asbestos or cardboard, as mentioned above.

If the information we provide is not enough, we recommend reading a book written by a stove maker - Polyakov I.S. “Stoves, fireplaces, sauna heaters, barbecues.” There, in addition to practical advice, you will also find information about the technology and stages of laying different stoves.

The order of the stove for the bath, or the pattern of laying bricks, is the most important element with which you can correctly lay the stove, while having minimal skills in performing stove work.

It is worth noting that, despite the abundance of ready-made metal stoves on sale, the traditional wood-burning heater still holds the palm in Russian baths. At the same time, the ordering of a brick stove for a bath, properly maintained, allows its design to be reliable, which will have a positive effect on the service life of your stove.

Over its thousand-year history, humanity has created several types of sauna stoves, which operate according to different schemes and based on different principles.

Moreover, even if you have a small stove for a bath, its arrangement will be individual. As for the most common designs, they are as follows:

- gray stove;

- black;

- white oven;

- heaters combined with a stove.

Black stoves, in principle, do not have a chimney, and the smoke here comes out of the room through the door. They are considered the most ancient and have existed in the world for centuries. Their advantage is the ability to obtain a large amount of steam with a small amount of fuel. The disadvantages include the need to wait for the fuel to completely burn out in the firebox.

A gray heater stove for a brick bath, as well as the arrangement for it, assume the presence of a chimney. At the same time, one of the advantages of such stoves is their high efficiency while warming up the steam room quickly enough. However, such stoves, just like black ones, require their owner to wait for the wood in them to completely burn out.

The most common in our time are the so-called white stoves, which are characterized by the presence of a completely closed chimney that does not release combustion products to the outside. However, they also have their drawbacks, for example, they take a very long time to heat the bath. In addition, a white brick stove for a bathhouse and its installation are difficult to implement, and not every householder can do it.

The most common in our time are the so-called white stoves, which are characterized by the presence of a completely closed chimney that does not release combustion products to the outside. However, they also have their drawbacks, for example, they take a very long time to heat the bath. In addition, a white brick stove for a bathhouse and its installation are difficult to implement, and not every householder can do it.

As for stoves with stoves, they are usually not used in the bathhouse, but are laid out in utility rooms when, for example, it is combined with a summer kitchen. In addition, such stoves can be built in a sink and are used to heat the water necessary for washing or washing clothes.

There are also unusual designs, for example, stoves for Kuznetsov’s bathhouse and orders for them. The author of such a stove claims that the efficiency of his brainchild exceeds 80%, however, if you are building a sauna for the first time and do not have sufficient experience in this area, it is better not to take risks and give preference to a traditional wood-burning heater.

There are also unusual designs, for example, stoves for Kuznetsov’s bathhouse and orders for them. The author of such a stove claims that the efficiency of his brainchild exceeds 80%, however, if you are building a sauna for the first time and do not have sufficient experience in this area, it is better not to take risks and give preference to a traditional wood-burning heater.

Furnace calculation and selection of materials

Before starting to lay the stove, it is calculated for a particular room. It is usually performed based on heat transfer in kcal/hour. In this case, the task of the calculation is to try to provide conditions in order to maintain the temperature in the room until the next fire.

Calculating furnaces is a complex procedure, and most homeowners are not able to complete it. Of course, there is the I.V. method. Kuznetsov, based on the average thermal power of a unit surface. However, it is better not to take risks and entrust all the calculations to an experienced stove maker.

Calculating furnaces is a complex procedure, and most homeowners are not able to complete it. Of course, there is the I.V. method. Kuznetsov, based on the average thermal power of a unit surface. However, it is better not to take risks and entrust all the calculations to an experienced stove maker.

After the stove for a brick bath is calculated and the order is selected, it will be necessary to start selecting the material for the masonry. The fact is that the purchase of this or that material and consumables for laying the stove completely depends on the masonry scheme. So, the main material needed for its laying is stove brick.

It is worth choosing red brick M-150, which is perfect for laying a Russian stove. The fact is that it can withstand temperatures up to 800 °C and perfectly resists mechanical damage. In this case, the combustion parts are laid out from fireclay bricks, which can retain heat for a long time and can withstand temperatures of 1600 C.

At the same time, the main signs of the quality of any brick are its fine-grained structure and the absence of inclusions and pores visible to the eye. Another method of checking is tapping with a light hammer. If during this procedure a ringing or clear abrupt sound is heard, then the brick is of high quality, but if it is dull and stretched, it is a defect.

In the case where nothing can be understood by sound, the brick is checked for cleavage, that is, it is dropped from a height or broken. In this case, a low-quality brick should crumble, and a good one should split into large pieces with a granular fracture. At the same time, it is always worth remembering that you cannot use sand-lime brick when laying any parts of the stove, so always try to purchase stove bricks or fireclay with a reserve. In some cases, however, you can use clinker bricks, but not silicate bricks.

In the case when you are laying out a brick stove for a bathhouse with your own hands, and also doing the ordering yourself, it is worth remembering that fireclay bricks are used for this in full size, 3/4 of the length, as well as in quarters and halves. This is how they are marked on all masonry diagrams.

As for the solution, as well as stove appliances, it is best to buy them ready-made. Of course, you can mix the solution yourself, but it’s better to just take the ready-made mixture and prepare it according to the instructions. In this case, you will get durable masonry and will not waste a lot of time mixing the solution.

As for the solution, as well as stove appliances, it is best to buy them ready-made. Of course, you can mix the solution yourself, but it’s better to just take the ready-made mixture and prepare it according to the instructions. In this case, you will get durable masonry and will not waste a lot of time mixing the solution.

Ordering sauna stoves

The order of stoves for a bathhouse is selected solely based on its design. For example, there are options when the stove operates continuously, and there are options when it is heated periodically and must keep the room warm for a certain time. In principle, a do-it-yourself sauna stove and arrangement are not that difficult to implement. However, for this you need to study the masonry diagram well and strictly follow the instructions attached to it.

In addition, a drawing of the arrangement of a brick stove for a bathhouse, equipped with a photo, may be very useful to you; as for the order of laying out the stove, it is as follows:

- Construction of the foundation and foundation. If your bathhouse is small, then a regular strip foundation will be sufficient for the stove, but you will definitely need to have good waterproofing.

- Preparation of solution and tools. If you prepare it yourself, you must soak the clay for it for 5 days. After this, mix with cement and sand in a 2:1 ratio.

- At the same time, when laying out brick stoves for a bathhouse, drawings with orders should always be at hand. The fact is that you will need to constantly check with them to avoid mistakes.

- The laying of the furnace begins with the zero row, in which a ventilation duct begins to form. At the same time, it is carried out layer by layer with strict adherence to the arrangement of bricks. In addition, during work it is necessary to periodically check the horizontality and verticality of each row, as well as monitor the correctness of the angles.

- All stove appliances are installed on their own row, for example, the damper is mounted on the 3rd row, the firebox doors are installed on the 8th row, and the metal box for the heater stones is installed on the 12th row.

- Next, the masonry proceeds according to the diagram, and special attention will need to be paid to the laying out of chimneys and voids in the stove, since the quality of its draft depends on this.

- The layout of the stove usually ends with 27 rows, on which a chimney is made to the length you need.

Naturally, a do-it-yourself stone stove for a bathhouse and the arrangement of other structures for it have their own characteristics, so it is worth carefully studying in advance the structure of, for example, the same Dutch oven that is sometimes laid out in a bathhouse.

In the event that you are not well versed in the stove business, it makes sense to invite an experienced stove maker to the construction site, who can give you very useful advice on laying out your stove. For example, there are some fire safety rules that should be observed when installing stove heating.

Nuances of laying out sauna stoves

The subtleties of installing a stove in a bathhouse include, for example, strict adherence to the layout diagram and the requirements of fire safety rules. This is very important, since almost all fires in baths occur due to the fact that the stoves in them were laid out incorrectly. At the same time, despite the fact that permission from the fire service to put a bathhouse into operation is not required, it has the right to periodically inspect such buildings for their fire safety, and if violations are detected, impose very significant fines on the owners of such bathhouses.

Thus, firefighters require unconditional compliance with the following rules:

Thus, firefighters require unconditional compliance with the following rules:

- It is necessary to maintain a distance from the furnace wall to the combustible structures of the bathhouse of at least 0.5 m. In cases where this cannot be done for objective reasons, it is recommended to protect such structures using a screen made of non-combustible materials.

- It will also be necessary to leave a gap of at least 1 of its diameter between the brick pipe and the wooden elements of the building.

- The existing gap between the roof and will need to be covered with a sheet of galvanized steel.

- It will be necessary to lay a metal sheet on the floor in front of the stove, which will protect the room from fire if coals from the firebox fall onto the floor.

In addition, in order to give the stove a pleasant appearance, as well as protect the bathhouse from fire, you can plaster it. At the same time, the plaster is painted very well, which will give your steam room some zest to the interior.

A brick stove is the main functional element of any Russian steam room, which is traditionally made of heat-resistant red brick. The construction market offers a wide range of ready-made stove designs, but bathhouse owners decide to build a Russian stove with their own hands.

A classic brick stove for a bathhouse with a heater, built with one’s own hands, makes it possible to safely heat the room, maintain optimal temperature conditions, produce clean and thick steam, and is a decorative interior element.

Selecting material for constructing a furnace

Currently, there are many available schemes for constructing a furnace, but a novice master is recommended to choose the simplest drawing.

What kind of brick should a stove be built from? Choosing the right building material is not easy. If you have limited financial resources, you can choose red brick of dubious quality.

However, the dimensions of such material rarely correspond to accepted standards; for this reason, quite wide seams can be obtained - up to 11 mm, which is absolutely unacceptable when constructing a stove.

Often, a sauna stove is built from fireclay bricks, which are 75% made of. This material is resistant to overheating and high humidity, cracking and deformation. In terms of technical and operational characteristics, fireclay bricks are superior to all existing analogues, but the price is much higher.

The firebox is built from fireclay bricks, and it is better to build a chimney from fire-resistant red bricks.

For construction work you will need clay, which you can get yourself or purchase at a specialized point along with bricks.

To build a brick stove, you need to prepare the following materials:

- fireclay;

- heat-resistant brick;

- coarse clay and sand;

- a grate, a door for the ash pit and combustion chamber, cleaning wells, a cast-iron stove and a grate;

- asbestos cord;

- zinc wire;

- corner;

- roofing felt

These materials are enough to build a simple brick oven with your own hands.

Preparing construction tools

To build a brick sauna stove with your own hands, it is recommended to prepare working tools:

- grinder with a circle;

- electric drill with a special attachment;

- wide plastic container for solution;

- Master OK;

- level;

- tape measure and pencil;

- metal strips.

This is a basic list of tools, but if desired, it can be expanded with additional equipment.

At the stage of choosing a place where a small brick oven will be located, as well as preparing a construction project, it is important to take into account the basic requirements for the future design:

- Firebox safety doors should face the door.

- The base for the stove device must be at least 75 × 75 cm in size and up to 22 cm in height.

- The shelves should be located along the wall near which the stove is installed.

- Heating stoves made of bricks are built in compliance with the technological gaps between the walls of the structures and the walls of the steam room.

Arrangement of the foundation

Laying brick stoves begins with laying out the foundation, which is the basis for any heating structure, ensuring its strength, reliability and durability.

According to the finished bathhouse design, markings are made at the construction site and a foundation pit up to 65 cm deep is dug. Its width should exceed the dimensions of the stove by 10 cm.

A layer of sand 18 cm thick is laid on the bottom of the pit and moistened with water, then covered with crushed stone, stones and broken bricks. All layers are thoroughly wetted and compacted. The pillow is kept for some time to shrink.

After complete shrinkage of the sand layer, removable formwork is installed, reinforced with an armored belt made of thin reinforcement.

Important! A technological gap of 12 cm must be left between the walls of the formwork and the earthen edges of the pit.

The formwork is filled with concrete mixture to the boundary level, which is 17 cm below the soil surface. The mixture is prepared in proportions - 1: 3 (three parts sand to one part cement) with the addition of the required amount of water.

After the concrete has completely hardened, the formwork is removed, and the existing voids are filled with fine gravel.

Folded roofing felt is used as a waterproofing layer for the foundation. The material is laid on a concrete base layer strictly according to the size of the site.

Mixing connecting masonry mortar

In order to get a reliable and durable brick stove for a bathhouse, it is important to knead it correctly. The accuracy of the proportions depends on the quality of the clay - its fat content.

To mix the solution, clay and sand are used in a ratio of 1: 2 (for one clay part, 2 sand parts). The clay is pre-soaked in a small amount of water.

To do this, the material is placed in a container, filled with water and mixed thoroughly. To simplify the kneading process, you can use a drill with an attachment. The clay is kneaded until it becomes sufficiently plastic.

Only after this is slightly damp sand introduced into it in parts and stirred. A well-prepared stove solution should be viscous.

One batch of mortar should not be too much or too little; it should be prepared just enough to be enough to complete 2-3 full brick rows.

Step-by-step execution of brickwork of the furnace

The procedure for erecting brick walls for a bathhouse is determined by the construction scheme - the order. The proposed step-by-step instructions consider alternate brick laying.

Bricklaying from 1st to 7th row

Beginning craftsmen have a completely logical question: how to build a stove from the foundation (the first 7 rows)?

- The first row is laid out directly on the waterproofing layer of the foundation. The bricks are pre-wetted with water. Corner elements are made at a right angle, which is checked with a corner. The edges require careful measurement, which will prevent the appearance of unwanted gaps in the stove structure. In this case, the thickness of the finished joints between the bricks should not exceed 6 mm. To better stack the bricks, you need to properly mix the mortar.

- The second row of bricks is laid out in a similar way, with each subsequent element being located at the joints of bricks from the bottom row. Bricks for the third row should be laid according to the same pattern. A blower door should be installed here. It is fixed with thin wire and steel strips.

- Before proceeding with laying the next row, it is recommended to check the evenness of the walls being erected vertically and horizontally, as well as the accuracy of the angles. In this row, wells for ash and gratings for air ducts are installed. To do this, small holes of 1 cm are made in the elements with gaps for mounting the grate. Under the installed grille, the rear wall is made slightly rounded.

- In the sixth row, the installed blower door is fixed, and in the seventh row, the installation of the grate and firebox door is completed. To ensure safe heating of the steam room, the stove door must be made of cast iron. At the moment this is the most durable and heat-resistant material.

Bricklaying from the 8th to the 23rd row

- How to fold the stove from the 8th row until installing the chimney? When forming the eighth row, a partition is installed, which serves as the basis for arranging the chimney. Using a similar principle, brickwork is carried out up to the 14th row inclusive, on which metal channels will be installed. In this case, it is necessary to create a small opening in the front wall of the furnace for the vertical installation of the water tank so that it is in full contact with the channels.

- To lay out the fifteenth row, ½ bricks are used, which are placed at a slight angle among themselves. This will serve as the basis for the dividing partition. Up to the 18th row, the laying of bricks is carried out by analogy with the first rows of the structure.

- When laying the nineteenth row, a door is installed to allow steam to escape. Next, metal strips are installed, with further laying of the remaining rows. This is necessary for securely fixing the door frame for steam exhaust and installing a hot water tank, which is lined with bricks.

- From the 23rd row, a chimney pipe is installed, which determines the final height of the structure.

Installation of a chimney pipe

How to fold a stove with a chimney after completing the construction of brick walls? The furnace construction manual provides for the preliminary selection of a pipe, which in type and functional features must correspond to the design of the future furnace. For a lightweight design, it is recommended to choose a small pipe made of lightweight and heat-resistant material.

When choosing, you should take into account the appropriate wall thickness of the chimney pipe, which cannot be less than ½ the thickness of the brick. The diameter of the passages for the chimney pipe should be of a similar size.

The length of the upper part of the pipe, located above the roof, should not be less than 55 cm. To equip the smoke exhaust duct, a connecting mortar based on cement or lime is used. The clay-sand mixture is not suitable for such work, since under the influence of precipitation it will quickly wash out and form condensation on the inner walls of the pipe.

The chimney pipe with a minimum number of bends must have a total length of at least 5 meters. The finished design can be equipped with a special one.

Plastering surfaces

Having studied the ordering process, now every novice master knows how to build a brick stove for a Russian steam room. Having completed the main construction work, you can proceed to plastering the structure. Applying plaster improves the visual characteristics of the stove and prevents it from catching fire.

For plastering, you can use a solution based on clay, gypsum or an asbestos component. To ensure better adhesion of the plaster on the surfaces being treated, it is recommended to add regular table salt to the finished solution. If you don’t want to bother with mixing the solution, you can purchase ready-made clay-sand mixtures.

Before plastering begins, the furnace structure must be dried. All surfaces are thoroughly cleaned of the connecting solution, the seams are cleaned 10 mm deep. Some craftsmen apply the plaster solution to a pre-attached mesh of metal wire, which serves as a sheathing.

Using a spatula, spread the finished solution onto the moistened surface in two layers. The first layer should have the consistency of thick sour cream, and the second layer should be denser and more viscous. The thickness of each layer can reach 10 mm.

After applying the solution, the surface is rubbed and leveled.

A finished brick stove with your own hands can be lined with ceramic tiles, tiles, or simply painted with white paint.

Now any master has an idea of how to build a Russian stove from refractory bricks. Having previously prepared your own drawing of the future structure will allow you to bring any idea to life without involving outside help.

Despite the fact that a brick oven takes longer to warm up, it is able to provide more uniform heating of the steam room and the absence of “cold zones”. Experienced steamers claim that it is comfortable to be in such a room even at high temperatures.

Brick kilns are quite complex devices, and their laying requires special skills. You can do it yourself, but only if you strictly follow the laying scheme (order) and know certain subtleties.

Do you need a foundation?

Such a structure will have significant weight, so a solid foundation must be built before installing it. Some experts argue that if the building is built on a solid foundation, a separate construction for the furnace is not required. However, in swampy areas or in northern regions, where due to temperature changes even carefully compacted soil will “play”, it is better to provide separate foundation.It is undesirable to cut load-bearing beams and logs for its construction, rafters and floor beams for the removal of the chimney, so it is better to choose a place for the stove before the construction of the building begins.

Important! Such a foundation should not be tied to the main one, since due to the large temperature difference during heating, the expansion coefficient will be too large. The distance between the main and furnace foundations should be at least half a meter.

Foundation for a sauna stove

Construction of the foundation for the furnace

Pit depth is determined based on the properties of the soil: with high density, 20-50 cm is enough, in loose soils it goes deeper by 50-100 cm. Its width should be a brick larger than the base of the stove. Before laying begins, sand is poured onto the bottom, which is thoroughly poured with water to compact it, then crushed stone or broken brick is laid and compacted tightly.Important! The cement-sand mortar completely hardens and gains strength for at least a week, so you should not build a heavy stove until it is completely dry.

The surface of the foundation should not reach the floor level to the height of two bricks. 2 layers are placed on the finished base waterproofing: roofing felt impregnated with tar mastic or roofing felt treated with bitumen solution. The gaps between the foundation and the floor are filled with sand and compacted.

The foundation can also be made of solid brick or rubble (large building stone of irregular shape), which are laid on a base filled with cement mortar. The penultimate row of the brick foundation is also covered with a layer of waterproofing.

Laying the foundation

Start of masonry

What is order?

In order call a detailed masonry diagram indicating the order of placement of bricks in each row. For work, you should choose the order of the stove corresponding to the size of the steam room. For example, if the heater is located above the firebox, to ensure maximum heating, the firebox is made at least 0.5 m. For a steam room volume of up to 12 square meters. m and a 40 liter water tank, the size of the heater with dry steam will be 0.77 × 0.5 m. The height of the firebox should be about 0.5 m.In the absence of proper experience, it is better not to change the scheme. If the room is non-standard, and any changes are still required, it is better to show the adjusted order to an experienced specialist.

The masonry diagram in any drawings always starts from the zero row. It is necessary to bring the foundation to the floor level. It is not difficult to determine the height of the future structure: in the diagram, each division is 10 cm and is equal to the average height of the brick.

The two pictures below show an example of a brick oven with a water tank and its arrangement. The diagram shows that the bricks are laid in different ways: with a spoon (on their side) or with a bed (the wide part) down.

Stove-heater with tank

Arrangement of a heater with a tank located at the top

Sand-clay solution

Cement does not tolerate high temperatures well, so it is not used for ovens. Masonry is made using a solution of clay, mined at a sufficient depth without impurities of earth and other foreign inclusions, and sand.

Start of masonry

Before starting work, the clay should stand in water for several days and soften. Before combining with sand, it is thoroughly mixed with water to the consistency of thick, thick sour cream. The remaining lumps can be broken up using a construction mixer or a drill with a special attachment.

To prevent pebbles and small stones from getting into the narrow seams, the sand is carefully sifted. To lay refractory bricks, clay and sand are mixed in proportion 1:2. To prevent the solution from drying out, the batch is prepared in small portions. The solution should be slightly rough, as elastic as possible and should lie without tears.

But the fat content of clay varies, and the fatter it is, the more sand should be in the solution. That is why experienced stove makers check the viscosity by shaking it from a stick or trowel.

The normal thickness of the layer remaining after shaking is 2 mm. If it is less, clay is added. If the consistency of the solution resembles plasticine, and after shaking, more than 3 mm of solution remains, more sand should be added to the mixture.

Brick selection

If you plan to fire with coal or gas, high-quality refractory bricks with frost resistance of up to 25 cycles are used for the work. For a wood-burning stove, it is better to use its refractory (Gzhel type) variety. Hollow and silicate types are not used, as they quickly collapse under the influence of high temperatures.Sometimes, in order to save money, only the firebox is laid out with refractory (clamotte) bricks, and the rest of the furnace is covered with ordinary silicate bricks. But, since their coefficient of thermal expansion is different, you should not combine them in a harness.

You can check the quality of a brick by simply tapping it with any hard object. If there is no defect, the sound will not be dull, but ringing, “metallic”. Products with visible cracks, foreign inclusions or excessive porosity should not be used. High-quality fireclay bricks have a rich yellowish (sand) tint, while unfired bricks have a pale and dull color.

Fireclay brick

Furnace laying

Before laying, to improve adhesion and prevent dehydration of the mortar, the brick is soaked in water for several minutes until bubbles are released. Fireclay bricks can only be immersed in water briefly to remove dust.The first row of bricks should be laid dry on the foundation without using a sand-clay mixture. During subsequent laying, the thickness of the mortar layer should be 3-6 mm. The layer and the bonded part of the brick are coated with the solution. At the selected place, you should move it slightly, and then, tapping with a trowel, press it tightly.

Bricklaying

To strengthen the structure, bricks are laid with offset next row by 30-50% and overlap the joint. When working, you will definitely need halves and quarters. To prevent cracks from forming, cutting It is better to do this using a grinder equipped with a diamond blade.

Laying halves and parts of bricks

In the places adjacent to the bricks, the door is insulated with asbestos, 4 strong wires or strips of galvanized sheet are screwed to it using bolts and washers, which will be laid in the seams of the masonry. To achieve density according to the size of the wire, grooves are cut in the bricks.

Door installation

Door installation

To ensure better heating, bath stones are placed on a steel or cast iron grate. The fewer there are, the drier the steam will be in the room. In a Russian bath, the weight of stones is at least 50-60, in a sauna - 30 kg.

in order to ideally select bricks in size, each row of them is first placed dry without mortar, the excess length is carefully trimmed, the bricks are numbered, and then assembled in a row already with mortar;a stove laid out unevenly will not last long, so even the slightest deviations should not be allowed: after laying each row, it is better to check the horizontal and vertical using a level; the accuracy of the angles is additionally determined using plumb lines or a corner;

In order for the grate and doors to last as long as possible, it is better to choose not steel, but more refractory cast iron;

in a wood-burning stove, the grate and door are located at the same level; when heating with coal, the grate should be 20 cm below the firebox;

when laying the grate, be sure to leave gaps for thermal expansion; To do this, if necessary, the brick is cut to the required size;

Grate installation

A small ventilation slot should be provided above the door, which will protect it from overheating, or the bricks should be cut in this place with a wedge;

to ensure better air flow and complete combustion of fuel, grate bars are laid only along the blower channel;

halves and quarters are best used in the top rows;

To prevent the clay from cracking over time, the oven can be reinforced with clay and a steel mesh; the fastening wire for it is already provided in the masonry.

Construction of pipes and chimneys

Iron chimneys have a serious drawback: when temperature changes, condensation forms on them, which “attracts” soot, so it is better to build them from brick.Important! Only whole bricks are placed in the chimney. Due to the risk of them falling out, the use of halves and cracked parts is unacceptable. The chimney wall must be perfectly flat. Otherwise, lumps of soot will accumulate in the corners, and the shaft will quickly become clogged. It is advisable to round off the protrusions along the entire smoke path.

When installing a chimney, several rules must be followed:

Hailom called the system of passages connecting the chamber with fuel and the chimney; the size of its lower part depends on the width of the firebox and on average is 3/4 of a brick; its cross-sectional area should be about 60-65% of the total area of the chimney;

all places where smoke passes should be immediately cleaned and the remaining solution should be completely removed;

it is unacceptable to narrow the chimney channel - it must be the same along its entire length; in addition, its cross-section cannot be less than the cross-section of the hail, and its total length from the edge of the pipe to the grate is at least 5 m;

Chimney laying

When laying a chimney and firebox, it is better to place the bricks with the most burned side facing the fire and smoke;

if the chimney is too short the smoke will not have time to cool down, and the heat will simply fly away into the chimney;

to protect against fire where it passes through the ceiling, the pipe is additionally lined with bricks and wrapped in heat-resistant material;

Finishing the junction of the pipe and the ceiling

The height of the pipe after the roof ridge must be at least 0.5 m;

so that damage can be easily determined, the pipe is whitewashed with lime mortar: in this case, the places of smoke leakage can be easily identified by traces of soot.

Test firing of the stove

It is believed that a stove that is perfectly dried before the first lighting will last longer, so it is better to leave it for a couple of weeks with the doors open until it is completely dry. If there is no rain, the pipe valve is also left open. The room itself should also be ventilated these days.Test kindling is carried out with a small amount (about 500 g) of paper. This is done in order to determine the presence of draft and remove residual moisture from the oven. The blower should be completely open at this moment. After this, the oven is left for another day.

Advice. If it's damp outside, the fire may not burn well the first time. In this case, in order to “push” the air upward, you can burn a newspaper rolled into a tube in the upper cleaning door or view.

Subsequent kindling with wood chips and a small amount of firewood should be carried out carefully. The maximum amount of fuel can be added only after several kindlings. An ideally built stove does not smoke and heats up evenly. You can determine the degree of heating by touching different parts of its surface with your hand. A brick oven should also cool evenly.

The density of the masonry and the absence of cracks are determined by burning materials that produce a lot of smoke in the smoke channel. If cracks are found through which smoke will pass, they are covered with a solution.

Smoke movement pattern