Metal roofs are widely used in private, multi-apartment and industrial housing construction. There are several types of roofing materials made from metal. What unites them is the main thing: each of them is based on a metal sheet coated with special protective compounds. Today, there are two large groups of metal roofs on the construction products market:

- Flat or folded. These include coatings made of rolled or sheet steel;

- Profiled. This category includes coverings made of metal tiles and corrugated sheets.

In turn, in each of these groups the material differs in the type and thickness of the sheet, type of coating, weight, size, shape and performance properties.

Metal roofing with sheets fastened together with seam joints was produced long before other, more modern types of roofing materials appeared on the market. This option has not lost its relevance even now. This is due to the fact that this type of metal roofing has a number of advantages:

- Versatility. Due to the flexibility of metal sheets, it is possible to install a metal roof of almost any configuration: flat, single-double and multi-slope, hip, hipped, attic;

- Durability. The service life of metal roofs ranges from 30 to 100 years, depending on the type of material used in the work;

- Environmentally friendly. Metal roofs do not emit harmful substances or unpleasant odors;

- Excellent performance properties. If the technology was not violated during the work, seam roofs have a high degree of tightness and do not allow moisture to pass through;

- Good maintainability. If individual sections of a metal seam roof are damaged, they can be quickly replaced. In addition, such roofs do not require special care; mold and moss do not form on them;

- Easy to install. Due to the light weight of the material, a lightweight rafter system and sheathing can be made, and complex tools and a large number of workers are not required to complete the work;

- Fire resistance. The material does not support combustion and is not subject to spontaneous combustion;

- Aesthetics. Today, the market offers a wide range of materials for seam roofs: both galvanized steel sheets or coated with polymer compounds, and products made of non-ferrous metals, aluminum and copper. This allows you to implement various design projects.

The disadvantages of metal roofs include a low level of heat and noise insulation, but this problem is eliminated by using special insulating materials in the under-roof space.

What is seam roofing

Metal roofs got their name due to a special type of joining of individual sheets, a seam. There are several types of such connections:

For the installation of metal roofs, there are two types of seam plates on the market: sheet and roll. In the first case, there is a restriction on the use of material: the angle of inclination of the roof should not be more than 30°. The roll analog can be used on any type of roof.

In addition, it is possible to cut the sheet to the required length. In this case, material consumption is reduced, the number of joints is reduced and, as a result, the performance properties of the metal roof are improved. If the work is carried out correctly, due to the absence of horizontal joints, it is possible to achieve 100% waterproofness of the roof.

Roofs made of various metals: from steel to copper

When planning to install a metal roof, you should pay special attention to the choice of material. The main materials used in the production of roofing coverings are steel, aluminum, copper and zinc-titanium sheets. Each of them has its own characteristics, advantages and disadvantages.

All these options are used for arranging seam metal roofs. It is also important to take into account that all additional elements necessary for installing a metal roof: ventilation outlets, drains, connecting parts and nails must be made of the same metal as the main covering. Only in this case can you achieve an ideal result.

Modern materials for metal roofing

Metal tiles and corrugated sheets are relatively new roofing materials with excellent aesthetic and performance characteristics. For the manufacture of profiled sheets, either steel or aluminum is used. In the first case, in addition to galvanizing, polymer compounds are also used for protection.

The main materials used to create a coating that protects metal roofs from external influences are:

- Polyester;

- Pural;

- PVDF;

- Plastisol.

By applying a protective coating, it is possible not only to improve the performance properties of metal roofs, but also to give profiled sheets and metal tiles different colors and textures.

Both options are widely used when installing metal roofs of various configurations. Metal tile roofing is usually done in private households. The use of roofing metal profiles is much wider: depending on the type of sheet, its thickness and profile height, it can even be used for arranging existing metal roofs at industrial facilities.

High-quality installation of metal roofing is the key to success

All types of metal roofs are quite simple to install. The material is light in weight and easy to transport and store. However, a person who does not have the skills to carry out roofing work may encounter a number of difficulties.

For example, to install a seam metal roof, you need a seam bending tool, which not every owner has available. Rolling folds by hand is a very labor-intensive process, and the quality of the work performed may not be at an adequate level.

The installation of metal tile roofs or roofing made from corrugated sheets does not require special tools, but to obtain a high-quality result, it is better to entrust the work to professionals. Our company’s specialists are always ready to help and carry out all metal roof installation work efficiently and in a short time.

The installation of metal tile roofs or roofing made from corrugated sheets does not require special tools, but to obtain a high-quality result, it is better to entrust the work to professionals. Our company’s specialists are always ready to help and carry out all metal roof installation work efficiently and in a short time.

Prices for folding:

Copper seam metal roofing - price from RUB 2,799/sq.m.

Galvanized seam roofing - price from RUB 3,404/sq.m.

Aluminum seam roofing - price from 1981 rubles/sq.m.

Prices for metal tile roofing

Prices for metal profiles

Economy class coating, polyester coating type, metal thickness, mm 0.4

Standard/economy class coating, type of coating: galvanized, metal thickness, 0.5 mm

Standard class coating, coating type - double-sided polyester, metal thickness 0.5 mm

| Profile view | units change | Cost, rub/m2 |

| C-8 | m. sq. | 215 |

| MP-18 | m. sq. | 225 |

| MP-20 | m. sq. | 225 |

| MP-40 | m. sq. | 225 |

| C-21 | m. sq. | 220 |

| MP-35 | m. sq. | 245 |

| NS-35 | m. sq. | 245 |

| S-44 | m. sq. | 245 |

| N-60 | m. sq. | 290 |

Seam roofing made of steel is a classic type of roofing in Russia, which has been successfully used for many years and has proven itself to be relatively inexpensive, reliable and durable. A steel seam roof will last at least 50 years.

Advantages of steel roofing

- Light weight. Approximately 4.2 kg/sq.m. with a thickness of 0.55 mm;

- Flexibility and plasticity. Possibility of laying steel strip on radius roofs;

- Full set. Almost all additional elements, accessories and fasteners of the desired color are available;

- Geometric stability. Steel coating, compared to copper or titanium-zinc, is less susceptible to deformation due to temperature changes throughout the year.

To create a seam roofing made of steel, rolled galvanized steel with polymer coatings is used. Depending on the type of coating, the texture and color palette of the roof changes. Seam panel paintings are manufactured directly on site. This is a very labor-intensive job that requires a high level of roofer skill, but the result is worth the effort.

A properly designed and technologically installed seam roof made of galvanized steel is guaranteed to last at least 50 years.

You can familiarize yourself with the range of steel for standing seam roofing or facades using the links below.

ArcelorMittal

The Belgian company ArcelorMittal is the largest metallurgical enterprise in the world, supplying its products to most well-known brands. The produced steel is a high-quality material with high performance characteristics.

from 500 R

for 1 m²

from 500 R

for 1 m²

Ruukki

The Finnish company Ruukki, founded in 1960, produces roofing steel with various coating options (Pural, matte Pural, polyester and Purex). Thanks to special developments, Ruukki steel is close to copper in its ductility; it is suitable for all architectural forms and all types of buildings. Silent and flexible, it does not tear during installation and is designed for a long service life.

from 500 R

for 1 m²

from 630 R

for 1 m²

from 640 R

for 1 m²

from 680 R

for 1 m²

Corus

Corus Group is a British metallurgical company formed in 1999, and is currently one of the largest steel and aluminum producers in Europe. Corus produces coiled steel, including those coated with polyester and plastisol. These materials have high performance characteristics suitable for the Russian climate. They resist temperature changes and UV rays well, withstand heavy loads, and also have excellent dirt-repellent properties.

Steel roofs are currently of limited use due to metal savings. Roofing steel is used in residential construction to cover eaves, gutters, dormers, protruding decorative elements of buildings and for drainpipes. In addition, roofing steel is used for repairing existing steel roofs, as well as for covering industrial buildings, belts, sandstones and window flashings on building facades.

Base for steel roof

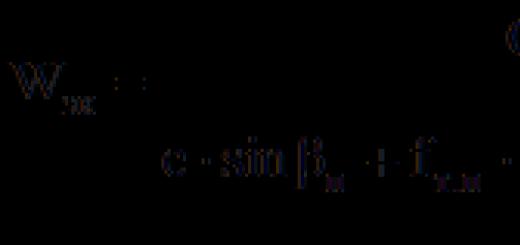

Steel roofing, made from galvanized or black sheets of roofing steel, is laid on a lathing made of 50x50 mm bars. The bars are placed every 250 - 270 mm (Fig. 1).

Along the eaves, ridge, gutters and roof ribs, sheathing is carried out by continuous covering with 50x20 mm boards. Boards can be edged or unedged. Sheets of roofing steel are secured to the sheathing with clamps made from strips of sheet steel. Both bars and boards are pre-antiseptic. The sheathing is secured to the wooden rafters with bolts and nails. The rafters and sparse sheathing have the same slope - 16 -24°. The sheathing for a steel roof is made of pine, spruce, fir and aspen. The moisture content of the wood used to make the sheathing is 12%.

Molded materials (bars and boards) arriving with a humidity of up to 25% are stored in stacks with dense packing, and with a humidity of more than 25% - in stacks that ensure natural drying of the materials; A dense roof is installed over the stack. Roofing parts are stored indoors, laid on pads that protect them from bending, breakage and ground moisture. To protect the wood of the roof sheathing from rotting and extend its service life, the wood is impregnated with antiseptics, coated or painted. The service life of wood increases if it is covered with drying oil when dry. To significantly increase the service life of dry wood, it is coated with resin.

To increase rot resistance, the wood of the sheathing must be treated with water-soluble antiseptics, since the sheathing is not intended to be moistened during operation. The most widely used water-soluble antiseptics include sodium fluoride and fluorosilicone, copper sulfate, and sodium dinitrophenolate. Sodium fluoride NaF is a white powder, slightly soluble in water, odorless, does not destroy wood and iron, which is very important for steel roofing. Sodium fluoride is used to impregnate and coat wood in the form of a 3% solution at a temperature of 15°C. Sodium fluoride cannot be used in a mixture with lime, chalk, or gypsum. Sodium silicofluoride Na2SiF6 is a powder that is poorly soluble in water and is close in antiseptic properties to sodium fluoride. It is used in the form of a hot solution mixed with sodium fluoride in a ratio of 1:3. Due to its easy flammability, sheathing wood must be protected from fire by treating it with fire-retardant chemicals - fire retardants, which either melt at high temperatures or emit gases that prevent combustion. Evenly soaked dry wood at high temperatures does not ignite, but only smolders. Impregnation of wood with fire retardants is carried out in the same way as impregnation with water-soluble antiseptics, which gives better results than coating with fire-retardant paints.

Steel roof installation

Steel roofing is made from galvanized and black roofing steel sheets measuring 1420x710 mm. Before use, determine the correctness of their dimensions and the squareness of the corners. Sheets with deviations from standard sizes are sorted and subsequently used to prepare roofing elements that do not require exact dimensions, for example, for drainpipes and drains. On standard sheets, bulges are removed with hammers. To prepare various products, the material is marked onto the workpieces using measuring instruments and tools, and marks are made on the metal. Then, according to the markings, the steel sheet is cut with various types of scissors, depending on the thickness of the sheet. Pictures are prepared for ordinary covering of roof slopes, eaves overhangs, wall gutters, and gutters. The picture is an element of the roof covering, the edges of which are prepared for a seam connection. Usually they are made of two sheets, less often single. The paintings on the roof are connected into strips the length of the slope, i.e. from the cornice to the ridge. The strips are attached to the sheathing with narrow strips of roofing steel (clamps), which are inserted into the standing seams when they are bent at one end, and nailed to the sheathing beam with the other. Double lying folds are coated with mortar, and the folds of galvanized paintings are soldered. Roofing sheet steel for preparing pictures or links of drainpipes must have smooth planes with right angles. Figure 2 shows the types of seam joints.

Seam joints are divided into recumbent and standing according to their appearance, and into single and double according to the degree of compaction. Rebate dimensions in Fig. 30 are given for sheets with a thickness of 0.45 - 0.7 mm. For thicker sheets, the dimensions of the bends increase by 20%. The long lateral edges of the sheets running along the slope are connected by standing folds, and the horizontal ones by lying ones. Roof slopes are covered with strips made up of sequentially connected patterns. To cover the roof, 85 - 90% of double paintings and 10 - 15% of single paintings are required, which are sometimes necessary to complement the stripes. The eaves overhang begins with the installation of pins with brackets and T-shaped crutches, nailed to the sheathing. The pins are placed along the axes of the water intake funnels, and the crutches are placed 700 mm apart from each other with tolerances of ±30 mm. The distance between the pin and the nearest crutch should be 200 - 400 mm (Fig. 3).

|

|

a - general view; b - recumbent fold; c - standing seam; d - a picture of two sheets; d - fastening sheets with clamps. |

1 - pin with bracket; 2 - water intake funnel; 3 - tray; 4 - flooring of grooves; 5 - rafter leg; 6 - cornice flooring; 7 - sheathing; 8 - picture of the wall gutter and eaves overhang; 9, 13 - nails; 10 - crutch; 11 - cornice overhang; 12 - hook for gutters; 14 - clasps. |

Pictures for covering the eaves overhang are connected at the watershed with a single recumbent seam. Gutters, trays, funnels of drainpipes and the pipes themselves are elements of a single water intake system. Bends of lying folds are made in the direction of the slope. The top part of the trays is secured under the sheets of the gutter, and the sides are fastened to it. The funnels of the drainpipes should be attached not to the trays, but to the descent of the eaves with a special stepladder; When attached to trays, the funnel together with the tray may come off if clogged or frozen. The design of the wall gutter and water inlet funnel is shown in Fig. 4.

Drainpipes They are also assembled from pre-prepared links, consisting of a trunk, elbow and funnel. The pipes are hung vertically on the walls and secured with pins with brackets installed every 1.4 - 1.5 m. The installation of pins with brackets and the installation of drainpipes are carried out simultaneously with the laying of brick and large-block walls. Sheets of non-galvanized steel are coated with drying oil before being laid in place. In the future, such a roof requires systematic painting once every 2 to 3 years. Galvanized roofs do not need to be painted. The advantages of a steel roof are its low weight (approximately 5 - 10 kg/m2) and the ability to create relatively small slopes (16 - 24%). When the roof is adjacent to a wall or firewalls, the edge of the row covering must be inserted into a groove against the wall masonry; in this case, the depth of the furrow must be at least 7 cm, and the height - at least 13 cm; the edge of the row covering inserted into the furrow must end with a vertical bend at least 10 cm high (see Fig. 3). In this case, the edge must be strengthened with spikes driven through 250 - 300 mm into the joints of the masonry or into tarred plugs embedded in the masonry.

When covering gable overhangs, belts, sandriks, turn-off strips are installed at the outer edge of the sheets. The side walls of lanterns and dormer windows should be covered with sheets connected to each other and with row coverings. When covering dormer windows of a semicircular shape, the sheets should be joined with a double seam, and dormer windows with flat slopes should be joined with a ridge. In places where the row covering adjoins the chimney, the width of the vertical bends of the edges of the collar placed under the otter must be at least 150 mm on the ridge side and 100 mm on the bottom and side sides. The gap between the pipe laying and the collar must be filled with putty. Chimney caps must have overhangs of at least 20 mm. The caps are fastened to the pipe using wire and nails driven no closer than into the second seam from the top of the pipe.

Steel roof repair

When repairing a steel roof, two types of patches are used in certain places: along the width of the picture, when the roofing sheets are worn out on the plane, and intermediate ones - when there is damage in or near the ridges. To apply the patch, a sheet is prepared with some allowance for the size of the worn areas. Allowances are used for connections. The damaged area is uncovered, a patch sheet is placed on this area, connecting it to the old sheet using standing and lying folds. The patches are joined by double rebated seams in valleys and wall gutters. On particularly flat slopes, the patches are connected to the old sheets by soldering the seams. Before installing the patches, they must be dry-dried, and after final connection with the old sheets, they must be painted over with weather-resistant paint compounds, while simultaneously painting over the joints to prevent corrosion.

If repairs to steel roofs are carried out in separate patches, then roofing paste, mastic, canvas, and tarpaulin are laid on holes in the roof ranging in size from 30 to 200 mm. If holes up to 30 mm in size are repaired without patches, they are covered with red lead putty, hot bitumen, or roofing mastic. Holes 30 - 40 mm around should first be cleaned of dirt, rust and coated twice from the roof and attic. Repair of gutters, eaves overhangs, gutters and drainpipes is carried out more often than the roof itself, since these elements are often subject to mechanical stress when ice is carelessly chipped and snow is thrown off; moisture is retained on these parts of the roof longer.

If half of the entire roof has become unusable, replace the entire roof with new sheets of roofing steel. The sheet material of the roof covering is especially susceptible to corrosion at the joints or between the sheathing bars on the attic side when the normal temperature and humidity conditions in it are disrupted. Connecting parts such as nails, bolts, wire are made of non-galvanized steel and at the points of their connection with galvanized sheets of roofing steel, an electric couple is formed, which acts destructively on galvanized steel. In this case, it is recommended to lay one or two layers of roofing material. The same phenomenon is observed when using non-galvanized clamps when installing drainpipes made of galvanized steel sheets. A sheet steel roof becomes unusable due to highly developed corrosion processes if the roof slope becomes insufficient, causing water stagnation. If it is necessary to replace the entire roof or most of it, it is necessary to install sheathing with a changed slope angle. When partially replacing a steel roof, work on preparing and laying roofing panels is carried out in the same way as when installing new steel roofs. Well-preserved old sheets removed from the roof are reused for row covering on the southern slope. They are pre-cleaned, cut around the perimeter, dried and painted. It is not recommended to use them for critical parts of the roof, such as valleys, eaves overhangs, etc. Only new sheet steel should be used for them. All folds, both standing and lying, are carefully coated with red lead putty before they are compressed.

In order to save steel, roofs with a high degree of wear can be repaired using rolled materials. Before starting work, defects in the sheathing are eliminated, then gutters, slopes and drainage devices are repaired. The torn sections of the roof and swollen areas are secured with nails, and the roof surface is cleaned of debris and rust with metal brushes. Cloths of rolled materials are laid along and across the standing seams of the roof (Fig. 5).

When covering longitudinally along standing seams, triangular cross-section slats of the same height as the seam are nailed on both sides. Then the surface of the roof and bars is covered with hot bitumen, onto which sheets of material are glued; the work is carried out from the cornice to the ridge so that each subsequent row overlaps the previously glued one by 8 cm. When covering with transverse stripes, the standing seams are first bent to the plane of the roof. The work is carried out from the cornice to the ridge, gluing the panels with hot bitumen. Each row is laid so that the next one overlaps it by at least 8 cm.

Repair of drainpipes may involve partial replacement of individual links, elbows, funnels or their complete replacement. When changing individual straight pipe links and elbows, you should first lower the lower part of the pipe barrel by 8 - 10 cm, having first freed it from the tightening and stirrup. The part being replaced is then removed, a new one is put in, it is secured at the top end in the stirrup, and then the lower part of the pipe is lifted and connected to the new one. When completely replacing the drainpipe, installation begins from the bottom. When painting a repaired roof, it is necessary, if possible, to use drying-free paint compositions, for example, grade A coal varnish, the so-called Kuzbasskraska, which is obtained by grinding coal tar varnish with red lead in ball mills. Before applying Kuzbasslak to a steel roof, the surface is primed with divinyl acetylene paint. Painting steel roofs in hot weather, in the sun, during rain, on surfaces that have not dried out from rain or dew and at temperatures below +3°C is not allowed. Roofs made of non-galvanized sheet steel are painted with oil paints, which must contain red lead or chromium oxide as a pigment. These paints are available ready-to-use or thickly grated. For the latter, the required working viscosity is obtained by diluting with drying oils.

In modern construction, metal roof has become more relevant than ever. Next we will talk about the structure of this type of roof and its main properties.

Like any stage of construction, metal roof equipment is accompanied by financial costs and takes a lot of time. Therefore, at the design stage, it is necessary to become familiar with the technological process and materials used during the construction of a metal roof. To calculate the number of steps of a staircase to the roof, use the online calculator for calculating stair steps.

Over the past years, the most commonly used material during the construction of roofing structures is a metal sheet. This is facilitated by the wide range of metal sheets on the market and the relative ease of assembling the roof during installation work.

Long service life and higher strength compared to other types of roofs also contribute to the increasing popularity of this type of roofing. Compared to roof coverings that were used until recently, metal tiles has a number of advantages:

- Long service life without additional investments;

- No need for additional roof maintenance work;

- High mechanical strength, and as a result, excellent performance in terms of resistance to gusts of wind, rain, snow, and icing;

- Easy installation;

- Low flammability;

- High economic efficiency.

One of the most effective and at the same time simplest options is pitched metal roof.

Also widely used metal roofs contributes to a wide range of different tones of metal tiles, which is limited almost only by the taste of the customer of the material.

The texture of this material suits any shade of color, so your structure will look original for a long period and be recognizable from anywhere in the landscape. After all, the roof affects the perception of the house as a whole, while diversity metal roof paint colors will allow you to bring to life the most daring projects.

It is worth noting that although metal roofs a little more expensive during construction compared to classic materials, but they more than pay for themselves during operation. After all, repairs to this type of roof are only necessary due to mechanical damage, which happens quite rarely.

So, a classic slate roof will require major repairs in 15-20 years, while a metal roof will last at least 60 years.

As in any business, during construction metal roofs It is necessary to use the services of qualified builders who guarantee the quality of work.

Due to the high popularity of this type of roofing, it will not be difficult to find a good contractor who will not only perform the work efficiently, but also help you choose the right quality materials. When choosing a contractor, you should ask him to show examples of work already completed and interview their customers about the integrity and reliability of these specialists.

You should not grab the first team you find, because there are probably specialists on the market who will perform high-quality work at a lower price.

Properties of a metal roof.

Of the positive qualities of metal tiles As a roofing material, it is worth noting the following:

1. The long service life of the roof ranges from 30 to 50 years, which is much longer than that of classical roofing materials, the service life of which is up to 20 years. Often famous metal tile manufacturers They provide a guarantee of up to 50 years on their products. And if during the warranty period there is a premature failure of the roofing material, the manufacturing company will carry out warranty repairs of the roof at its own expense. It is also worth noting that a metal roof can be built directly on top of the old coating, which is guaranteed to significantly reduce the customer’s costs due to the absence of costs for dismantling old roof structures.

2. High resistance to various colonies of mold and fungi allows for successful operation in various climatic zones for a long period without additional costs.

3. The low flammability of metal tiles will prevent the roof from igniting and, as a result, significantly reduce the likelihood of a fire in the building.

4. Significant mechanical strength provides a high degree of resistance to various natural phenomena, such as strong wind, hail, squall, earthquake, severe frost.

5. Thanks to the availability of a wide range metal roof covering, which imitates various textured surfaces, such as pebbles, wood, bitumen shingles, tiles, etc., opens up wide scope for various design solutions, which is important during the construction of a modern building. It is envisaged to both paint the already assembled roofing structure and select a metal covering pre-painted in the desired color.

6. Thanks to the presence of a glossy surface, metal roof significantly less susceptible to heating by direct sunlight, which reduces the cost of cooling the roof.

7. Because basically metal roof covering Made from recycled materials (scrap metal), this material is environmentally friendly, which is important for environmental protection.